GOAL

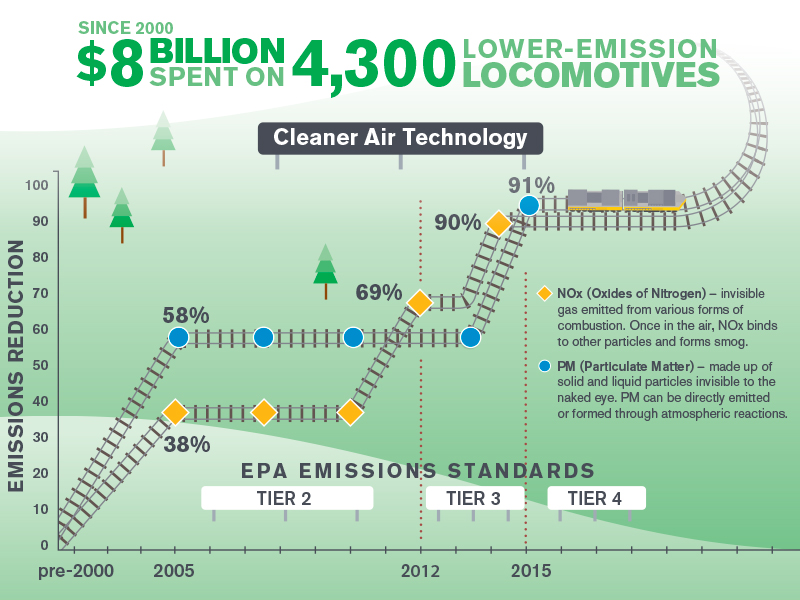

Our goal is to reduce locomotive fuel consumption rate by 0.5 percent annually from 2015 to 2017, an adjustment from last year's 1 percent goal for the same timeframe. Measured on a gross ton basis, this will result in a greenhouse gas emissions reduction rate of 0.5 percent annually. With an uncertain economy and demand outlook, we will continue to evaluate our locomotive fuel consumption rate.

Union Pacific continues exploring opportunities to deploy technologies that save fuel and optimize train scheduling. Our senior leadership is focused on this objective, and its success is directly tied to compensation based on our performance review process.

Reducing our fuel consumption remains a corporate priority, and we strive to strike an appropriate balance between financial returns, environmental performance and social commitment.

PERFORMANCE

Union Pacific produced 11,683,549 metric tons of Greenhouse Gas emissions from fossil fuels in 2015, which is down from 2014, due primarily to a decrease in freight volume. Union Pacific's emissions from biomass sources were 129,600 metric tons, including 35,534 from renewable fuels.

Scope 3 emissions from employee travel totaled 19,803 metric tons. Employee travel includes rental car fuel and commercial air travel. We worked with suppliers to identify their Scope 3 emissions on behalf of Union Pacific. Suppliers representing an estimated 26 percent of our Scope 3 spend produced emissions totaling 266,746 metric tons in 2015, compared to 338,693 in 2014.

As part of the company's landfill diversion initiatives, we supply used wooden railroad cross ties as a fuel source in co-generation plants to produce electricity. We estimate that the consumption of 3.1 million ties resulted in 458,753 metric tons of greenhouse gas emissions.

Union Pacific's 2015 greenhouse gas inventory was verified by GHD. Union Pacific works with Trinity Consultants to compile our GHG inventory. GHD and Trinity Consultants are independent organizations.