2019 Building America Report Menu

Operating Safely

Safety is Union Pacific’s No. 1 priority. As a company, we continuously look for innovative approaches to enhance the safety of our employees, our communities and the customers we serve. Our success is measured by reportable injury and derailment rates, which are provided to the Federal Railroad Administration. We invest in training, research and development, and public education – all with the goal of increasing rail safety awareness and, ultimately, creating an incident-free environment.

- Rail Safety Maintenance

- Innovation at Work

- Positive Train Control

- Safely Handling Hazardous Materials

- Safety Through Security: Union Pacific’s Police Department

- Cybersecurity

- Keeping Employees Safe

- Public Safety

- What's Ahead

Maintenance of Way employees work near Columbus, Nebraska.

Rail Safety Maintenance

Rigorously maintaining quality rail infrastructure is foundational to our ability to safely operate. It helps prevent derailments, provides a safe path for train crews and avoids shipment delays for our customers.

Union Pacific continuously inspects railroad tracks, locomotives and other equipment. Our track inspection program customizes schedules and techniques to examine each rail line, mile by mile. We inspected more than 2.5 million track miles, enough to cover our 32,000-mile network more than 79 times.

Despite efforts to strengthen our rail infrastructure, Federal Railroad Administration (FRA) reportable derailments worsened 12.7% from 363 in 2018 to 409 in 2019. A derailment occurs when at least one wheel comes off the track. In many cases, the impacted cars and locomotives remain upright. The majority of these incidents are attributable to human factors. We are targeting additional training and resources in the affected areas of our network to provide employees the necessary tools to complete their tasks. We also continue to monitor and revise train make-up and handling rules, as appropriate.

Safety Inspection Fleet

We use state-of-the-art equipment to regularly inspect rail lines. Geometry cars use an optical gauge measuring system, consisting of lasers and cameras under the rail car, to produce real-time track geometry images. The system evaluates track structure wear and tests for defects to help prevent derailments, maintain track health and increase track longevity. Union Pacific’s two evaluation cars, featuring military-grade navigation systems, cover a combined 70,000-80,000 track miles per year – enough to annually traverse our main lines at least twice.

We have four Gauge Restraint Measurement System (GRMS) vehicles positioned across our system to identify signs of wear or potentially weak spots in the track. Each vehicle is capable of testing up to 60 miles of track daily, specifically focusing on curved sections. To simulate the force generated by a locomotive, the GRMS vehicle applies 9,000-10,000 pounds of lateral force to the track. Its operator verifies and addresses any potential defect. We used GRMS vehicles to aid inspection of more than 12,500 track miles.

Union Pacific’s Precision Measurement Vehicle (PMV), designed and built by employees, is among the most advanced truck-based survey platforms in the industry. The PMV captures high-definition, 360-degree video and acquires data using an advanced inertial navigation system and under-vehicle mounted cameras. The data collected is integrated into employee training simulation models, helping familiarize train crews with territories. It also helps with system mapping by transmitting GPS locations of critical facilities, such as control points and road crossings, to Union Pacific’s Positive Train Control system. We currently use two PMV units, which together measure more than 8,000 track miles per year.

Currently in pilot testing, our Locomotive Track Geometry System attaches to a regular locomotive hauling freight. This system is capable of detecting track abnormalities, communicating in near-real time the type, severity and location to a data facility for verification and potential remediation. Using locomotives to test track geometry allows us to cover a larger footprint while evaluating conditions with an actual train. We believe this technology has the potential to cover up to 150,000 track miles per year.

Autonomous Boxcar Improves Track Health

Union Pacific’s Engineering Department proved you don’t have to think outside of the box(car) to have an ingenious idea. In collaboration with a vendor, it created the Autonomous Track Geometry Measurement System (ATGMS) to aid in track inspection. The ATGMS is housed in a regular boxcar and powered by solar panels. It consists of GPS, a camera and laser system positioned underneath the body, and an inertial measuring pack that senses movement left, right, up and down.

Attached to a train hauling freight, the ATGMS looks for track abnormalities, communicating the severity and location to a data facility for verification. If validated, an email and voicemail go to the appropriate field manager to start the process of visual inspection and potential remediation.

Testing track more frequently makes it possible to compile data that Union Pacific’s Engineering Department can use to build predictive track models. These models help predict what may happen in different track areas in the short- and long-term, allowing maintenance and track programs to be more efficient and drive Unified Plan 2020.

The ATGMS allows Union Pacific to test the track without putting it out of service.

Innovation at Work

At Union Pacific, we believe innovation is any change making us better. It can be a big idea leading to large-scale improvement or something smaller that impacts an employee’s day-to-day activities. We leverage both high- and low-tech approaches. That can mean tweaking a process by leveraging continuous improvement tools or using an existing technology for a new purpose.

Just as important as embedding innovative thinking into our culture is understanding that not all ideas will be successful. We know some solutions take more time to develop and require multiple iterations.

Drone Inspections

Unmanned Aerial Systems (UAS), or drones, are part of Union Pacific’s safety tool kit, collecting valuable information at derailment sites and natural disaster incidents. This allows us to assess our infrastructure and respond while keeping employees out of harm’s way. While we use live feeds, we also utilize drone data to create 3-D images. This helps our team find an incident’s root cause and, ultimately, mitigate future issues.

Union Pacific employees with a Federal Aviation Administration (FAA) Part 107 certificate, a government requirement to commercially operate drones, are stationed in all 14 service units across our network. Through 2019, more than 250 employees received training specific to FAA regulations and Union Pacific policies, and were equipped with drones.

Union Pacific began training and supplying its police officers, known as special agents, with drones equipped with a loud speaker and thermal technology. They allow special agents to observe and speak with people trespassing along our right of way, often in remote areas. For example, a trespasser was spotted in the middle of the San Jacinto River Bridge in Channelview, Texas. In the past, the special agent had to temporarily close the track and walk on the bridge, over the water. Now, they can speak to the trespasser through a drone. The technology is also used for crowd control, general train and right-of-way inspections, as well as crime prevention and control. At year’s end, 49 special agents, representing approximately 39% of the team, were using these customized drones.

Special agents use a drone to speak with a trespasser on the San Jacinto River Bridge in Channelview, Texas.

Crystal Ball? No, Thanks – We Have Up Vision

John Miller, systems engineer, left, and Hunt Cary, vice president-Harriman Dispatching Center, Operating Services, helped create UP Vision, providing employees a real-time snapshot of Union Pacific's network.

The aptly named UP Vision is giving Union Pacific a glimpse into the future, arming our employees with the insight needed to proactively manage systemwide train performance. Built in-house by our IT team, the platform incorporates data from numerous sources into one easy-to-read display, color coding by performance every active train on the network.

The map loads at the system level, but employees can use filters to drill deeper and view by criteria such as location, train length, train category and stop duration. Data is automatically updated every 1.5 minutes, providing a real-time snapshot. For example, a local Operating manager can look at incoming trains in danger of becoming behind schedule and create a solution that protects the corridor’s traffic flow.

“When we’re reacting, the problem is often over, the cost is sunk and we don’t have a chance to fix it,” said Hunt Cary, vice president-Harriman Dispatching Center, Operating Services. “Seeing it early provides an opportunity to make decisions, correcting the situation or limiting the exposure to further issues.”

Track Repair Inventory Goes Mobile

Not every car traveling Union Pacific’s track carries our shield, but our employees still do their best to ensure each one operates safely and reliably. That’s where mobile billing (MoBi) comes into play. It’s an app designed to increase efficiency, allowing carmen to more easily track repairs.

The carmen use tablets or small hand-held devices to enter detailed descriptions of the maintenance performed on each car. In the past, another employee copied work notes into the computer system. Carmen say MoBi saves them time and ensures customers are accurately billed for the work Union Pacific employees do on foreign rail cars.

Leveraging Tech To Check Train Placement

Children playing at a train table mix and match cars, often putting their favorite up front, but for railroads, there’s a science to building trains. It’s called train makeup, and Union Pacific is leveraging technology already in place to ensure cars are in the correct order, so they can safely move from origin to destination. When building trains, we consider three things: operational efficiency, federal regulations (such as hazmat car placement), and the placement of loaded and empty cars (heavy and light) that could affect train handling. Taking these factors into consideration, computer modeling is used to build the roughly 700 trains that traverse our system every day.

AEI is a system used to keep track of rail equipment. Each rail car has an AEI tag – a small radio transponder located on its side containing equipment information. Employees working in railroad yards use handheld AEI devices to ensure trains are assembled in the proper order. As they travel the system, trains pass AEI readers located throughout our network and train dispatchers receive an alert if there is a placement error. He or she can then validate the error and make plans for remediation.

Carman Dave Cummings using MoBi in California’s Roseville Yard.

A Union Pacific train carries mixed freight through this winter wonderland in Klamath Falls, Oregon.

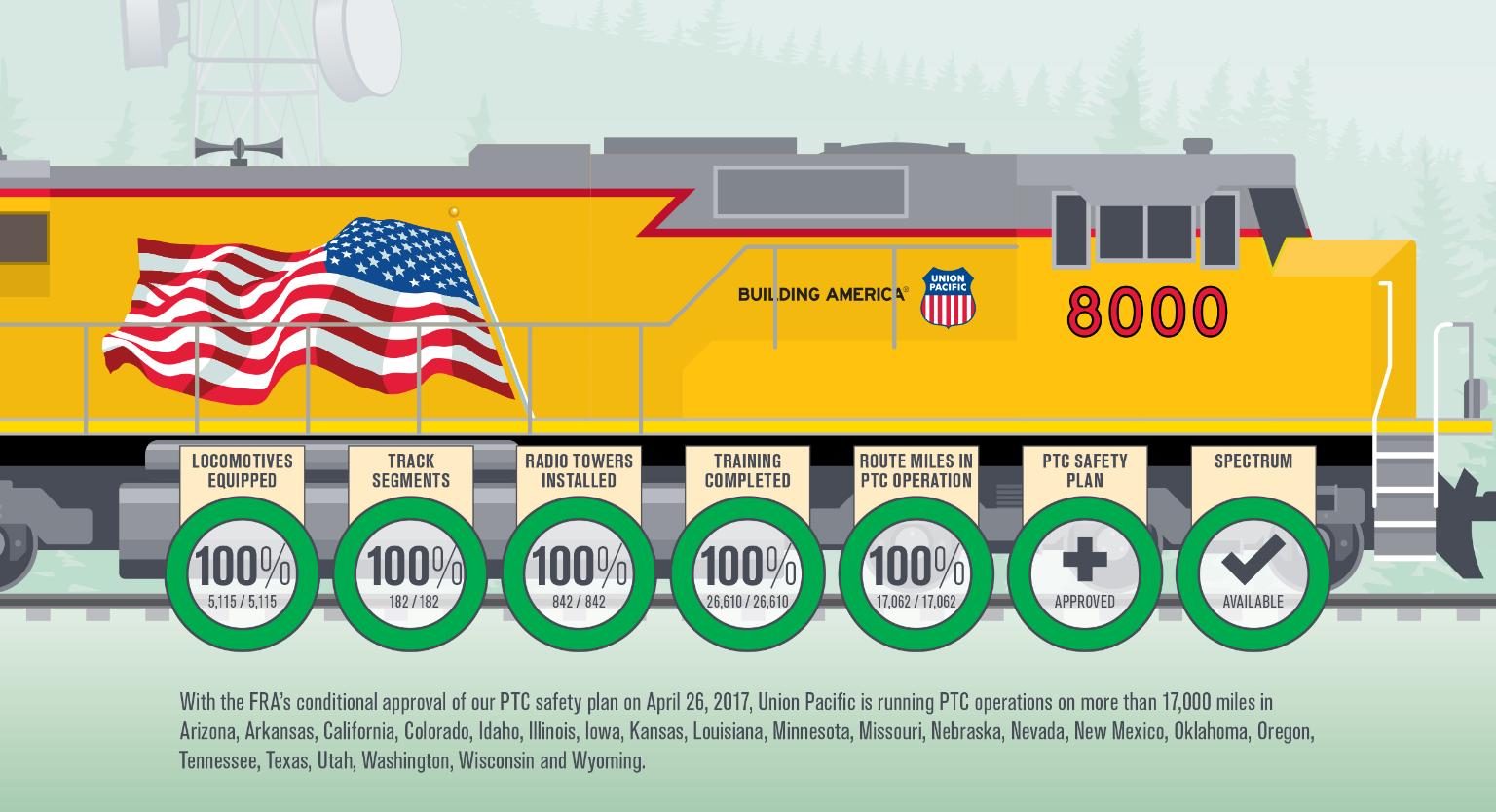

Positive Train Control

Union Pacific installed and implemented Positive Train Control (PTC) on 100% of required rail lines, including required passenger train routes. PTC is a complex, nationwide system of newly developed technologies that continuously relays critical information such as speed limits, train movement authorization, switch positions, work zone locations and other operational data. Visit up.com to watch a video showing how the technology works.

One of the most challenging parts of PTC implementation is ensuring system interoperability among all U.S. rail lines and locomotives. Given the various readiness levels of North American freight and passenger railroads, including publicly funded commuter lines and short lines, it is important that all railroads continue working together to maintain the health, safety, resiliency and fluidity of the rail network during PTC implementation.

Union Pacific hosts 25 freight and passenger railroads that must also achieve PTC interoperability by December 2020. Sixteen of these railroads are already compliant, accounting for 85% of Union Pacific’s interoper¬able PTC train miles. While our infrastructure is PTC-ready, we are working to be PTC-interoperable with the remaining partner railroads. Our expectation is that they will take necessary steps to reach interoperability on our network by mid-2020.

PTC Operation Status

With the FRA’s conditional approval of Union Pacific’s PTC safety plan on April 26, 2017, Union Pacific is running PTC operations in Arizona, Arkansas, California, Colorado, Idaho, Illinois, Iowa, Kansas, Louisiana, Minnesota, Missouri, Nebraska, Nevada, New Mexico, Oklahoma, Oregon, Tennessee, Texas, Utah, Washington, Wisconsin and Wyoming.

Union Pacific completed required employee training for 26,610 employees, a 100% completion. PTC education is ongoing as we retrain employees and introduce the system to new employees. Training materials are tailored to a variety of roles, including engineers, conductors, dispatchers, Maintenance of Way/Engineering, Mechanical, Signal, Telecom and IT employees.

Safely Handling Hazardous Materials

Union Pacific is obligated to transport hazardous materials by federal law, while trucks are not. Our commitment to safely haul this material is reflected in our 99.99% success rate delivering without incident.

Union Pacific focuses on accident prevention, preparedness, response and recovery. Our Hazardous Materials Management group consists of highly trained experts in hazardous material transportation safety who work with customers and inspect tank cars, ensuring products are properly secured.

Prevention

Through our prevention efforts, Union Pacific partners with customers, regulators and other stakeholders to conduct hazardous materials shipment inspections, sponsor training opportunities and actively participate in numerous industry initiatives focused on continuous improvement of those shipments.

Preparedness

While we work to prevent incidents, Union Pacific’s Hazardous Materials Management group regularly prepares for such an event. We do this by building strong relationships with first responders and other stakeholders throughout the communities where we operate.

Union Pacific provides fire departments and other emergency responders along our routes with comprehensive training on minimizing derailment-related impacts. We provided classroom and hands-on training to roughly 5,400 local, state and federal first-response agencies.

We also sponsored 75 emergency responders from 13 states to attend a rail-specific hazmat training center in Pueblo, Colorado. The five-day tank car safety training course focused on tank car assessments and repairs, and safely controlling hazardous material spills. Training also included a large-scale simulation of a hazardous material incident, providing emergency responders hands-on experience.

Over the last 10 years, Union Pacific trained more than 50,000 emergency responders throughout our network. We are a charter member of TRANSCAER® – a voluntary national outreach effort focused on assisting communities to prepare for and respond to a possible hazardous materials transportation incident. Union Pacific has won the TRANSCAER® National Achievement Award for 12 consecutive years.

We partner with stakeholders at the local, state, tribal and federal levels to establish geographic response plans. Conducting drills and exercises is another vital tool in preparedness. We regularly exercise our emergency response plans within our facilities, as well as with local, state, tribal and federal agencies.

Using our unique training tank cars and boxcars, we teach first responders on our system and provide various coaching opportunities and drills.

Response

If an incident involving hazardous materials occurs, Union Pacific’s Hazardous Materials Management group responds to safely and quickly mitigate any potential hazards to public health, environment and property. We do this by working with emergency response agencies and our network of specialized contractors, and by using internal resources, such as firefighting trailers and waterway spill containment systems.

All hazardous materials professionals are trained thoroughly in hazardous materials response and in the National Incident Management System. This allows for safe and effective response operations while working together with our public partners.

Recovery

Once an incident is under control, our hazardous materials professionals continue ensuring the communities, environment and Union Pacific’s network have properly recovered. We do this through environmental remediation and proper product handling practices. Union Pacific is capable of removing product from a damaged container and placing it into non-damaged containers. We accomplish this with our state-of-the-art transfer trucks and equipment, as well as numerous smaller transfer trailers that can safely and effectively remove liquid products. This creates a safer and more effective option for communities and reduces costs to our customers.

Union Pacific’s Hazmat team held a training exercise in Brownsville, Texas, with local fire departments, as well as Mexican firefighters.

Safety through Security: Union Pacific’s Police Department

The Union Pacific Railroad Police Department is a team of highly trained special agents dedicated to maintaining the railroad’s security and integrity. The department holds accreditation from the Commission on Accreditation for Law Enforcement Agencies (CALEA), which is considered the gold standard in law enforcement accreditation and recognizes agencies meeting the highest law enforcement standards.

The police department uses security monitoring technology to protect critical infrastructure from intruders around the clock, coordinating with U.S. Customs and Border Protection (CBP), the U.S. Coast Guard, the Federal Bureau of Investigation, the Department of Homeland Security and the Transportation Security Administration, as well as state and local law enforcement. Union Pacific was the first U.S. railroad named a partner in CBP’s Customs-Trade Partnership Against Terrorism.

Technology permeates our security program, including at international gateways, where safety and fluidity is critical. All rail cars entering the U.S. are inspected by VACIS gamma ray inspection devices. This technology is similar to an X-ray and can detect trespassers or hidden items. Additionally, cars are inspected by Union Pacific Police K-9 teams. In one case, a K-9 located more than 130 pounds of methamphetamine hidden in a rail car, which was confiscated and turned over to CBP.

Union Pacific’s special agents are an important part of the communities where we operate, educating the public about railroad safety. This occurs through joint efforts with local law enforcement agencies and at various community events, such as Back to School fairs and neighborhood gatherings.

New Crime-Fighting Tool

A camera mounted on a mobile trailer and flanked by solar panels may not sound high-tech, but this new crime-fighting tool is providing special agents the intelligence they need to detect and deter crime. The trailers are equipped with Thermal Radar™ that can track thermal images in rail yards and on trains without a special agent on-site to operate it. They capture images and send an alert, via email and text, to the assigned special agent in near-real time. Union Pacific police can assess the situation and, if necessary, notify local authorities to help resolve the issue. For example, train crews in Stockton, California, were noticing petty theft and vandalism. The thermal trailers provided the intel Union Pacific police needed to catch the suspects in action.

From left, special agents Daniel Guzman, Manuel Flores and Jeffrey Castillo host a safety fair in Tucson, Arizona.

New trailers, equipped with thermal technology, are easily moved to help solve crime and prevent unwanted issues.

Cybersecurity

Union Pacific is committed to maintaining web users’ confidence and trust. In general, they can visit our website without telling us who they are or revealing personal information; however, customers and other users can, if they choose, participate in additional secured applications. We may use cookies, tracking pixels and IP addresses to collect information to complete business transactions, enhance our services, better meet the needs and preferences of our customers and other visitors, and enhance the security of our online and digital properties. Our detailed privacy policy is available at up.com.

Data Security

Our Information Assurance team is responsible for the confidentiality, integrity and availability of Union Pacific’s infrastructure and assets. The team has robust processes and redundancies in place to prevent, detect and respond to potential threats. We also perform regular vulnerability scanning and system penetration testing to validate our security controls and assess our infrastructure and software applications. Like many organizations our size, we are continuously probed by malicious computers around the world. In 2019 alone, the Union Pacific network was probed 355 billion times. None was successful. Extensive incident response, disaster recovery and business resumption plans are in place and tested annually, ensuring the computing environment can withstand a wide range of scenarios.

Following the Sept. 11, 2001, terrorist attacks, the rail industry developed a security plan that includes a comprehensive blueprint for security enhancement and risk mitigation actions. It applies a unified, risk-based and intelligence-driven approach to rail security. In coordination with our industry partners, we regularly exercise and enhance cybersecurity prevention and incident response plans.

The Railway Alert Network is the industry’s intelligence and security information center. Each day, its staff reviews intelligence and related security information to produce analyses of terrorist tactics, malicious cyber activity, rail-related threats and incidents, and suspicious activity. Union Pacific uses these materials for threat hunting and in our security awareness communications.

Union Pacific employees are required to take security awareness training that includes information on data security policies and procedures. As a Fortune 150 company, Union Pacific receives over 30 million phishing emails each year. These emails are attempts to gain access to company or private information. Employees are regularly coached on how to identify phishing attacks, and how to avoid being victimized.

Data Protection

Union Pacific is committed to protecting the security and confidentiality of our data and that of our customers, employees and contractors. Although the U.S. has not enacted widespread regulation, such as the European Union’s General Data Protection Regulation, a patchwork of state laws and regulations govern personal data collection and use. Union Pacific developed a program to comply with the California Privacy Act, the most comprehensive state law, which took effect Jan. 1, 2020. Specifically, Union Pacific worked to increase transparency around our data collection and use procedures to enhance our ability to respond to inquiries and requests regarding a person’s data.

Keeping Employees Safe

Our safety performance did not measure up to the last three years’ record-setting performances. The employee reportable injury rate, measured by the number of injuries for every 200,000 employee-hours worked, increased nearly 11% to 0.90 compared to 2018, despite the decrease in the number of personal injuries due to reduced volume. Half of the injuries were sprains and strains. We are committed to engaging with employees to talk about being attentive to risks they may encounter in their daily work.

Two of our employees did not return home, and that is unacceptable. Their deaths impacted their families, communities and our Union Pacific family. We honor their memory by working toward an injury-free railroad. Union Pacific continues to improve technology, enhancing processes and fostering a culture focused on operating safely.

Safety First What Would Your Family Do Without You?

In September, we asked employees systemwide to stop their work and have candid, thoughtful discussions about how to make their workplace safer. The Safety Stand Down began with a powerful video featuring employees who felt firsthand the impact of losing a team member. For some, their words were tough to get out. Others were on a mission, hoping their message – what would your family do without you – compelled employees to change behavior. One thing was true for all: they never thought it would happen to someone they knew.

“Familiar environments can reduce the perception of risk,” said Tom Lischer, executive vice president-Operations. “While we understand there is no intent to be unsafe, we must get back to the fundamentals, eliminate distractions and focus on the job at hand, preventing ourselves and our co-workers from getting hurt.”

Engineering gangs 9062, 9063, 9083 and 0062 stand down in Ogallala, Nebraska.

Alton & Southern employees participate in the Sept. 30 safety stand down.

| REPORTABLE EMPLOYEE INJURIES Per 200,000 Employee-Hours |

||

|---|---|---|

| 2010 | 1.37 |

|

| 2011 | 1.15 |

|

| 2012 | 1.01 |

|

| 2013 | 1.10 |

|

| 2014 | 0.98 |

|

| 2015 | 0.87 |

|

| 2016 | 0.75 |

|

| 2017 | 0.79 |

|

| 2018 | 0.82 |

|

| 2019 | 0.90 |

|

Courage To Care And Total Safety Culture

Our employees are our eyes and ears – they identify risks, initiate action to mitigate those risks and work to keep each other safe.

Courage to Care, a voluntary commitment made by Union Pacific employees since 2012, empowers each person to look out for their peers and “stop the line” on any operation that could result in an incident. We encourage employees to have candid safety discussions and share experiences to learn from each other.

Total Safety Culture complements these efforts. The employee-owned, voluntary process includes training, observations and feedback. Employees recognize each other for safe behaviors while intervening in a positive way to address at-risk actions.

Who You Gonna Call? Opcc

Ever need to “phone a friend” to ask a work-related question? Rather than going through a manual, Operating employees can now call a 24/7 help desk to receive immediate, job-specific answers from their experienced co-workers. The Operating Practices Command Center (OPCC) provides employees with accurate and consistent information, and ensures that safety protocol complies with local, federal and companywide standards across all 23 states where we operate.

OPCC members also are responsible for monitoring operating practices from both a technological and safety standpoint. From Union Pacific’s headquarters building in Omaha, Nebraska, they’re able to connect remotely to onboard systems and contact train crew members via radio, as a standard field manager would do. When there are issues, such as a derailment, the OPCC can use incident reports to help determine if mechanical issues played a role and help mitigate future risk.

Sam Thomason, senior manager-Systems Quality Assurance, Safety, takes an OPCC phone call.

Monitoring Performance And Embedding Safe Behavior

Union Pacific uses video technology across our locomotives and vehicles to monitor engineers’ and drivers’ performance, ensuring safety, security and situational awareness. On the vast majority of occasions, this proactive performance sampling validates and confirms our employees’ professionalism. It also increases our in-depth understanding of people’s response to different situations, enabling us to improve coaching and embed safe behaviors.

Most of our locomotives are equipped with in-cab cameras. We installed in-cab cameras inside approximately 600 locomotives, increasing the total number of equipped locomotives to more than 6,300. These complement external-facing cameras, providing a complete view of incidents. We also capture event recorder data such as train speed, throttle position, brake settings and horn use.

Many Union Pacific vehicles are equipped with DriveCams positioned below rearview mirrors to record 12-second video clips triggered by driving events such as hard braking, swerving or excessive speed. DriveCam captures images from eight seconds before an incident occurs to four seconds afterward, enabling trained, third-party personnel to analyze root cause of unusual driving behaviors.

Public Safety

Keeping our communities safe involves proactive outreach to raise awareness and prevent risky behavior near railroad tracks, but we can’t do it alone. We rely on our employees to be safety ambassadors in the communities where they live and work, and we collaborate with local law enforcement partners.

Approximately 95% of nationwide rail-related fatalities and injuries occur at railroad crossings or as a result of people trespassing on or near the tracks.1 Nearly all are preventable.

Engaging Communities Through Up Cares

Risky behavior near railroad tracks has sobering consequences, and the devastating outcome is something no one should witness. Our UP CARES program recognizes that the most compelling arguments for staying safe are often those delivered face-to-face. Our employee volunteers deliver rail safety presentations to pedestrians, motorists and professional truck drivers across our 23-state network. To request a safety presentation, visit up.com.

In 2019, 55% of crossing incidents occurred at crossings with active warning devices, and 22% of incidents were the result of drivers going around or through the crossing while warning devices were activated. Investigations reveal risky or distracted driving was the cause. UP CARES addresses this by partnering Union Pacific’s special agents with local and state police departments to observe driver and pedestrian behavior. Our goal is not to write tickets, but to have meaningful conversations that change behavior.

Union Pacific worked with the Conway, Arkansas, Police Department to host a community safety event.

National Rail Safety Week

In celebration of National Rail Safety Week Sept. 22-28, Union Pacific partnered with several law enforcement agencies and communities across our 23-state system to share life-saving messages, reminding drivers and pedestrians to use caution every time they cross the tracks.

We joined forces with National Transportation Safety Board (NTSB) member Jennifer Homendy, Safe Kids Worldwide, Metra, DuPage Railroad Safety Council and the City of Elmhurst to hold a safety event at the Metra Station in Elmhurst, Illinois, encouraging parents to talk to their children about rail safety. Illinois, along with Texas and California, has the greatest number of fatal and nonfatal injuries for pedestrian and vehicle-related incidents at railroad crossings. We believe teaching children about rail safety should go hand in hand with educating them about how to look both ways before crossing the street. Parents are encouraged to share and model these five behaviors:

- Only cross the tracks at a designated railroad crossing, marked by a sign or lights and gates.

- If lights are flashing or the gate is down at a railroad crossing, wait for the train to pass completely and the gate to go back up before crossing. It is never ok to try and beat the train.

- Don’t be tempted to walk on or along the tracks. Trains are at least 3 feet wider than the tracks on either side.

- A train can take up to a mile to stop. By the time the locomotive engineer sees someone or something on the tracks ahead, it is too late to stop.

- If you are using a cell phone, headphones or playing a game, remember: heads up, devices down when you cross the tracks.

From left, Liisa Stark, assistant vice president-Public Affairs, Union Pacific; Jennifer Homendy, National Transportation Safety Board member; Bruce Marcheschi,chief operating officer, Metra; Dr. Lanny Wilson, DuPage Railroad Safety Council; and Torine Creppy, president, Safe Kids Worldwide, share important safety messages at a news conference

Critical Call Dispatcher Ariel Glover works with, at minimum, four or five different systems simultaneously

Responding To Incident Reports

Union Pacific’s Response Management Communications Center (RMCC) processes emergency and non-emergency calls from communities across our 23-state network. The RMCC team operates 24/7, responding to emergencies, reports of vehicles stuck on railroad tracks, criminal activity and other concerns. On average, a single dispatcher may take 70-plus calls in an eight-hour period. Drivers and pedestrians can contact the RMCC by using the phone number posted near railroad crossings, 888-UPRR-COP (877-7267).

In addition to working with citizens, employees and public officials, RMCC dispatchers occasionally take unusual calls, such as requests from the Secret Service motorcade teams when transporting the president on or near Union Pacific property. The RMCC team also plays an integral role in tracking and coordinating inspections of military shipments across the network. When dispatchers aren’t taking calls, they are responsible for compiling and auditing reports, and providing notifications to state and federal regulatory agencies.

In 2016, the CALEA awarded a second distinguished accreditation to our RMCC team, recognizing an advanced standard of compliance across policy and procedures, administration, operations and support services. We are in a four-year cycle of accreditation maintenance and will qualify for our third distinguished accreditation in 2020. RMCC is one of only 100 public safety communications centers worldwide recognized for emergency response and professional excellence in this way.

Homeless Safety Awareness

Union Pacific owns and operates more than 32,000 track miles, many of which are in communities that have experienced a significant increase in their homeless populations. Despite our efforts, unlawful encampments are set up on our right of way, along with dumping, graffiti and other illegal activities by third parties. Homelessness is a growing social problem that state and local governments are struggling to get their arms around.

Our highest priority is the safety of our employees and the communities we serve. Trespassing on railroad property is unsafe and creates a hazard for the public, as well as for Union Pacific employees. On Nov. 13, Union Pacific and the City of San Jose, California, launched a safety awareness and citywide cleanup effort that ran for several weeks, focusing on areas along our tracks. This joint effort with the city was a pilot approach to address homeless encampments on our right of way with the goal of reducing illegal activity and improving public safety. In Santa Ana, California, we added another layer to our efforts by partnering with a nonprofit outreach group to offer community services to the people displaced by our encampment strategy. Following these successful partnerships, we implemented similar clean-up and assistance efforts in a number of communities across California.

Our special agents periodically patrol Union Pacific property and work with local contractors to prevent recurrence of encampments and illegal dumping. We also work with local authorities to enforce criminal trespass laws on our property and to deter other illegal activities. We are aware these enforcement efforts may further displace homeless individuals; however, we work collaboratively with local communities and service organizations to connect displaced individuals to existing services that can help them find a safe place to go away from active railroad tracks.

What's Ahead

Union Pacific will continue leveraging technology as we work toward our ultimate goal – operating in an incident-free environment. For example, Union Pacific is studying emerging technology to determine the best future use of drone technology for safety, security and efficiency across the railroad.

We continue to encourage community leaders to work with us to identify long-term solutions to solve the homelessness crisis. We are coordinating with local California agencies to find safe housing and are launching partnerships with City Net, a street outreach organization in the Los Angeles area, and Mercy House, a nonprofit organization that provides rapid response rehousing services and individualized plans for long-term success to support those experiencing homelessness.