My first job was delivering The Boston Globe to customers in my small hometown every morning before sunrise. I rode my bike, and I always dreaded the Thursday and Sunday papers that were bulkier in size. Mom was kind and would often drive me on Sundays, but the rest of the week was on me to pedal up and down those New England hills.

I knew my customers. Some liked their papers on the porch. Others were fine using the Boston Globe mailbox. I worked hard, took pride in being great at my job and always looked forward to the holiday season when I would get a few tips for the work I had done all year. To earn those tips and keep my customers happy, my goal was to be as fast and efficient as possible to ensure I delivered every paper on time or early. I loved figuring out ways to speed up my route, like folding the papers in advance or delivering to both sides of the street to reduce the weight of the load early so I could ride faster to more distant houses.

That was my introduction to supply chain optimization. Little did I know it would quickly become a passion, leading me to a career focused on that very thing – keeping supply chains moving.

Earlier this year, I joined Loup, a wholly owned subsidiary of Union Pacific created in 2017 by combining four UP subsidiaries into one all-encompassing freight transportation and logistics powerhouse. We streamline our customers’ supply chains and help them stay competitive, providing access to environmentally friendly rail and first- and last-mile trucking solutions. We take away variability and deliver our customers’ most critical, time-sensitive products.

After nearly 20 years in the railroad and freight transportation industry, I’ve seen a lot of changes in the world of logistics. While technology provides more data and tools than we could have ever imagined, even with those advancements supply chains remain incredibly complex and dynamic. Weather events, pandemics, geo-political relationships, and many other factors impact how we do business and how we ship. As companies manage their business with lean inventories and staff, they must have partners to help navigate the complexity.

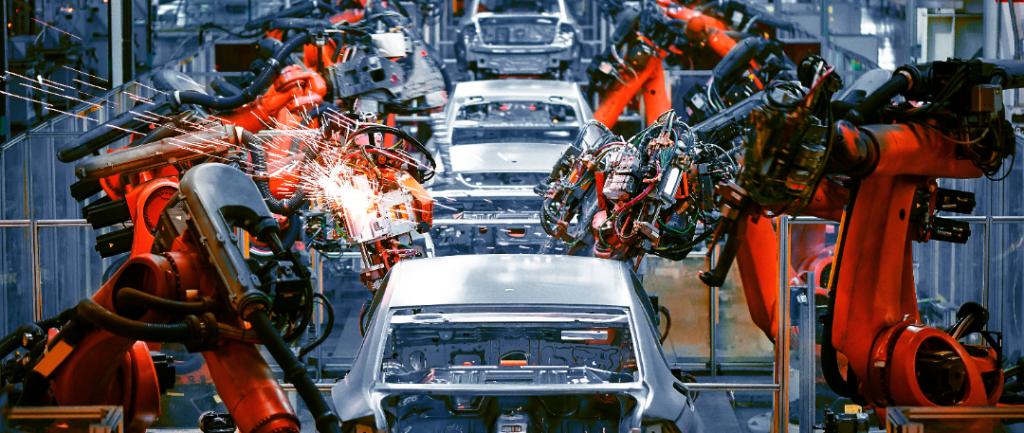

Take auto parts, for example. When you count every component that goes into making a new vehicle -- from the steering wheel to the smallest screws -- the average automobile is made up of approximately 30,000 parts.

Subscribe to Inside Track

Not only must those thousands of parts arrive in proper sequence at the manufacturing facility, they also must arrive within a 15-minute delivery window to meet strict just-in-time industry standards.

Now, a 15-minute window is not all that challenging if you’re delivering parts from across the street, but these parts are shipped from all over the world via multiple transportation modes.

In fact, the average auto part that moves via Loup’s door-to-door service travels nearly 1,800 miles before arriving at the production facility – via truck, train, and back on truck, to arrive within that 15-minute delivery window.

When it comes to managing tight schedules like these, shipment management technology is essential. Loup’s innovative technology team leverages technology to keep a close eye on shipments and mitigate potential delays. Through our shipment visibility and tracking product, ShipmentVision, we also provide our customers full visibility into their shipments’ journey from origin to destination – all in real time.

As supply chains continue to be tested and disrupted, we must remain nimble, adapt quickly to overcome the most complex shipping challenges, and always make transporting goods easy and seamless.

Those are essential requirements, whether you’re delivering auto parts via truck and train, or newspapers via Schwinn and pedal power. My passion for helping companies optimize their supply chains is stronger than ever.