Trains have operated for more than 160 years in the United States. Although the basic premise of how railroads run is still the same — a locomotive pulling rail cars carrying freight — the technology railroads use has evolved a great deal. Certainly, locomotive technology has changed. And rail cars have improved, too. But did you know railroads use other peripheral technology to make sure shipments travel safely?

From rail car x-rays to flying chainsaws, railroads employ some surprising but effective technology.

Chainsaws + Helicopters

If you’ve ever seen a low tree branch hanging over a sidewalk or roadway, you know it can make it hard to see and can even make it unsafe for cars and pedestrians. Trains encounter this same problem. Trees that grow next to railroad right-of-way can have branches that get too close to the tracks or too low for trains to pass underneath. To keep operations safe and sightlines clear, brush and tree canopies need to be removed.

In the past, overgrowth was cut back by crews on the ground. That is, until a Union Pacific employee who oversees vegetation control for the Mid-America Service Unit, had another idea. What if overgrowth could be removed from above?

The employee-led solution included affixing a chainsaw with a 24-inch blade to an 80-foot pole hanging from a helicopter. Helicopters lower the chainsaws to safely remove brush and tree canopies. While it might be an unconventional approach, it worked. The Mid-America Service Unit tested the method in the St. Louis, Missouri, area to North Little Rock, Arkansas, and found the average cost to remove vegetation dropped more than 70 percent. The new method was faster, too, covering five miles per day versus the previous half-mile benchmark. The new process also eliminates the need to re-cut vegetation for five years or even longer.

Today, these “flying chainsaws” are becoming the norm, not the exception, to remove canopies from Union Pacific right-of-way. The result is greater visibility and improved safety for railroad employees, customer shipments and civilians.

X-Rays and Inspection Portals

Railroads have their own police force who maintain security along the network, prevent theft, and ensure cross-border shipments are free of unauthorized cargo and passengers. These highly trained special agents use some unique technology to accomplish these tasks.

For instance, Union Pacific’s Railcar Inspection Portal (RIP) instantly provides a 360-degree view of rail cars passing through U.S.-Mexico crossings. By seeing every inch of a rail car (even underneath it!), railroad police use these images to spot anomalies on the outside of the rail car.

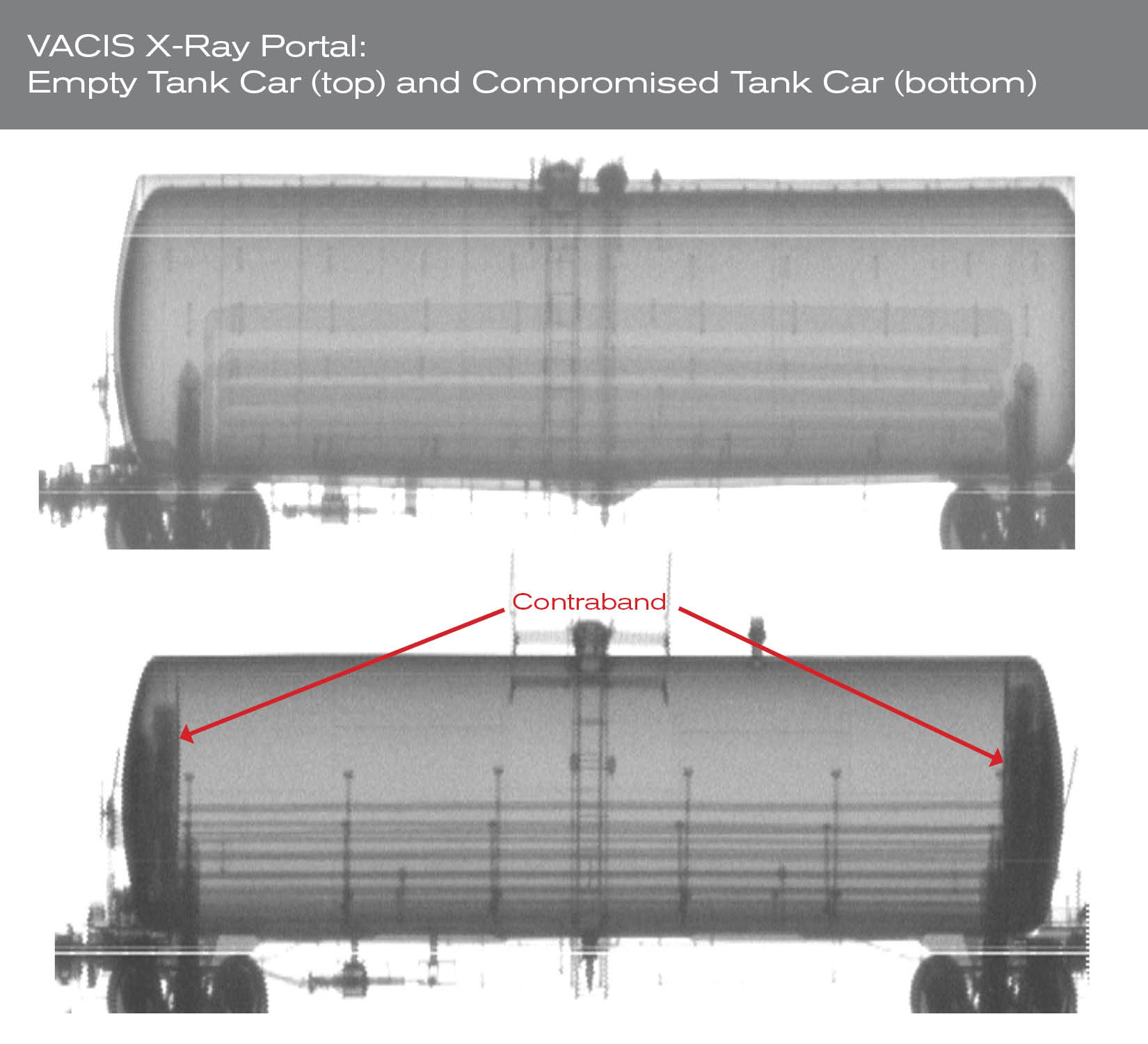

Railroad police work with Customs and Border Patrol (CBP) to inspect rail cars using VACIS, which takes an x-ray of the rail car looking for anomalies. Using these images, CBP can spot suspected contraband tucked inside the rail car and initiate a more in-depth inspection. The railroad police’s K-9 partners also help CBP sniff out contraband

High-Tech Safety Inspection Devices

Autonomous Track Geometry Measurement System

Railroads frequently inspect wheels, rail cars, and tracks to keep operations running safely and smoothly. Technology is making this process even safer and more precise, while playing an important role in preventing derailments.

- Ultrasonic Wheel Defect Detector

The Ultrasonic Wheel Defect Detector uses ultrasound technology to inspect the wheels on a moving train. Each year, this system checks more than 80,000 wheel sets and helps uncover wheel defects that otherwise would have gone undetected.

- Autonomous Track Geometry Measurement System

The Autonomous Track Geometry Measurement System (ATGMS) aids in track inspection. It is housed in a regular boxcar and powered by solar panels. The system consists of GPS, a camera and laser system positioned underneath the body, and an inertial measuring pack that senses movement left, right, up and down to assess track health.

- Wheel Profile Detectors

Along Union Pacific's more than 32,000-mile rail network, thousands of strategically placed sensors (Wheel Profile Detectors) are part of a sophisticated system that identifies rail car wheel defects like flat spots and worn bearings. In doing so, the system allows the railroad to troubleshoot defects that are either indiscernible or imperceptible by other means. They also help the railroad identify critical defects and prevent derailments.

Drones

Ultrasonic Wheel Defect Detector

Drones, also known as Unmanned Aerial Systems (UAS), collect valuable information at derailment sites and natural disaster incidents that helps Union Pacific assess infrastructure and respond accordingly — while also keeping employees out of harm’s way. Using live drone feeds as well as drone data to create 3-D images helps identify an incident’s root cause and mitigate future issues. Special agents also use drones to keep trains and railroad property secure.

Telematics

The next advancement likely to join the railroad’s technology roster is telematics. When these GPS-equipped devices are placed on individual rail cars, shippers, rail car owners and railroads can see a rail car’s status, location and condition in real time. Railroads are currently piloting this technology and a more complete rollout is scheduled for 2023.

Learn More

To learn more about how your freight can travel by train and benefit from these technologies, answer a few questions and an expert will be in touch.

Related Articles

- Railroad History: How the Rail Industry Has Evolved in 160 Years

- How Do Railroads Keep Cross-Border Shipments Safe?

- What Is Precision Scheduled Railroading?

- What Can a Railroad Build?

- Top Podcasts on Supply Chain Management, Freight Shipping & Logistics

- Surprising Railroad Inventions: The Ski Lift

- Rockets by Rail: A Stellar Achievement

- From Steam to Green: The Evolution of the Locomotive

- The Rail Industry Is Saving Millions of Gallons of Fuel a Year — And They’re Using “Cruise Control” to Do It.

- APIs Are Changing the Logistics Landscape — Are You Ready?

- How to Use Carbon Calculators to Reduce Transportation Emissions