Sulfuric acid is one of the most widely used chemicals in the world. It’s used to mine things like copper and lithium, which are integral to electric vehicle (EV) production, EV infrastructure and EV batteries. It’s also critical to the production of high-octane fuel. It’s used to produce things like carpet, fertilizer, and paper. Food-grade sulfuric acid serves as a preservative and aids in the production of foods like cheese and beer. And those are just a few examples.

In the 1940s, long before the term “circular economy” became part of the lexicon, Ecoservices’ predecessor Stauffer Chemical began recycling used (aka “spent”) sulfuric acid, thereby creating a circular production model.

Today, Ecoservices continues to regenerate spent acid to give it a second life. Doing so saves millions of tons of used acid from becoming waste while also producing more sulfuric acid for the marketplace. That’s not the only sustainable step Ecoservices takes — the company uses environmentally responsible transportation to help move sulfuric acid through the loop, and their product is key to improving fuel efficiency for vehicles, as well as aids in the electrification process.

A Brief History of Regenerated Sulfuric Acid

The Ecoservices Houston plant

The origins of regenerated sulfuric acid date back to World War II. At that time, the product was in high demand: It was used to produce ammunition and other explosives as well as high-octane aviation fuel to support the war effort. For those reasons, the government limited commercial use to ensure sulfuric acid was available for military purposes.

This left sulfuric acid producers in a bind: How could they satisfy their customers’ needs and those of the government? To please both parties, producers had to figure out a way to make more sulfuric acid without using more of it. Regeneration was the answer.

“Regenerating sulfuric acid was pioneered in the 1940s as part of the war effort to preserve the sulfur molecule, which had several critical applications,” said Sara A. Manstan, Director of Transportation and Logistics for Ecoservices. “Sulfuric acid used in the production of aviation fuel was disposed of after a single use prior to the development of the regeneration technology.”

The first acid regeneration plants popped up in Texas, Louisiana, California, and Indiana. All three were located near refineries from which they sourced spent acid.

Today, Ecoservices operates six sulfuric acid regeneration sites that regenerate a wide range of chemical spent acids.

How is Regenerated Sulfuric Acid Made?

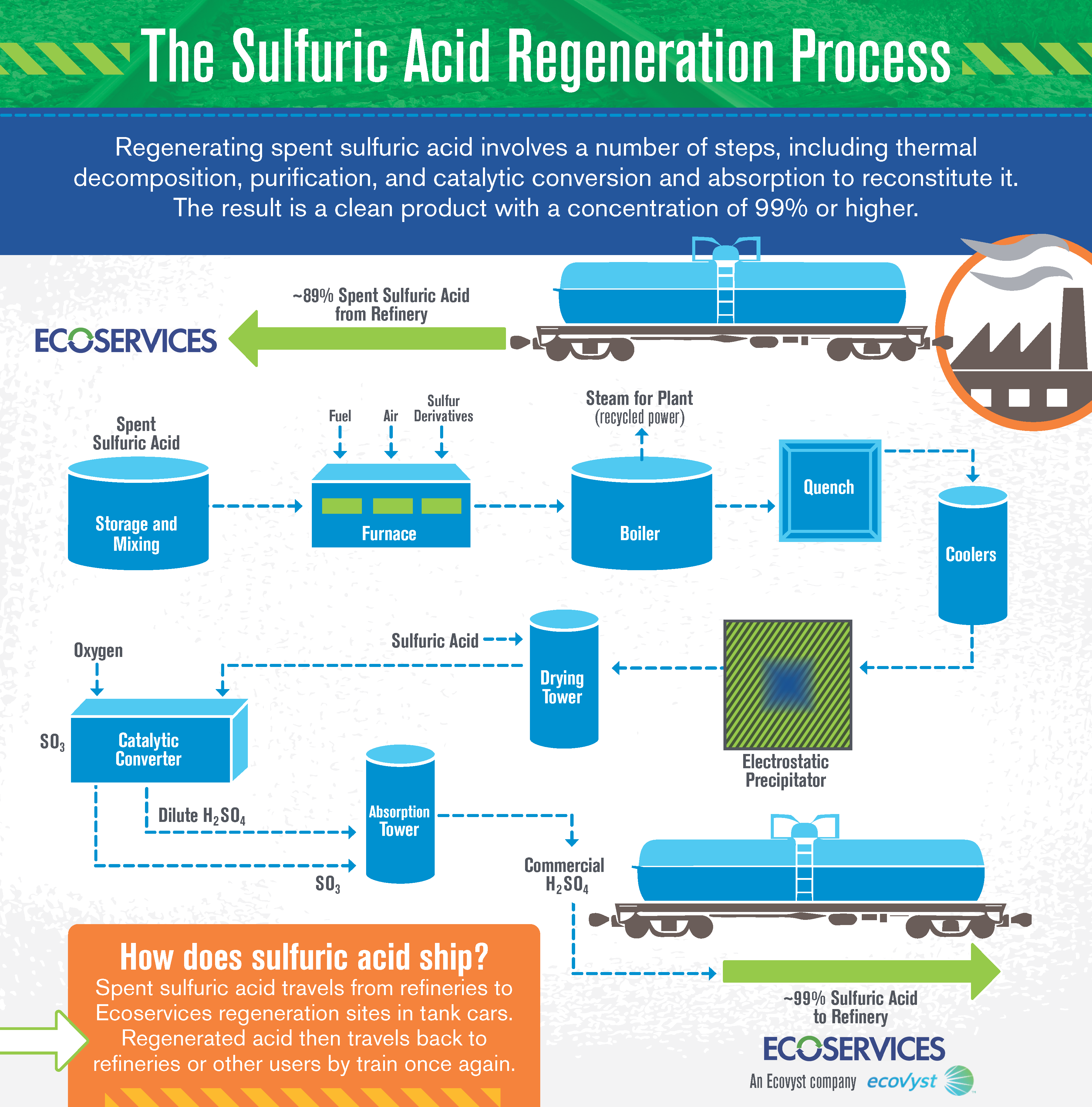

The regeneration process is comprised of multiple steps (see infographic for more details) but in the simplest terms, spent acid is incinerated until it becomes a powder and undergoes a purification process. Water is added to reconstitute it and it can then be used again.

“Spent acid, primarily recovered from the refinery alkylation process, is thermally decomposed to remove entrained contaminants, leaving a clean stream of sulfur dioxide gas,” said Ms. Manstan. “This gas stream is subsequently reconstituted as sulfuric acid through a process involving catalytic conversion and absorption.”

After sulfuric acid has performed its function, it can’t be reused before regeneration for two key reasons. Once it’s performed its function it becomes partially neutralized, which lowers the concentration. For instance, a refinery’s spent acid may have a concentration of 88%. But when that acid is regenerated, the result is a clean product with a concentration of 99% or higher.

Spent acid also picks up impurities that make it unsuitable for immediate use. The regeneration process removes these impurities and produces high-quality, high-concentration sulfuric acid, making regeneration a critical piece in creating a circular economy.

What Is Regenerated Sulfuric Acid Used For?

The Ecoservices plant in Dominguez, California

Among the most common users of regenerated sulfuric acid are refineries, which use it in the production of alkylate, a high-value blending component in gasoline.

“Regenerated sulfuric acid is primarily sent back to the refinery alkylation processes on an on-going recycling loop,” said Ms. Manstan. “The alkylate produced for blending in gasoline is used in high-efficiency engines with improved fuel economy. Alkylate is also cleaner burning (low sulfur, no aromatics), which limits emissions.”

As regulations call for improved fuel efficiency in passenger vehicles, the regeneration market has grown. The National Highway Traffic Safety Administration’s Corporate Average Fuel Economy (CAFE) standards regulate how far vehicles must travel on a gallon of fuel. The standards call for an industry-wide fleet average of approximately 49 mpg for passenger cars and light trucks in model year 2026 by increasing fuel efficiency by 8% annually for model years 2024 and 2025, and 10% annually for model year 2026. Regenerated sulfuric acid helps achieve these goals due to its role in making high-octane gas used to power high-efficiency engines.

In addition to gasoline production, regenerated acid has several other industrial uses.

“Regenerated acid is used in a wide variety of industrial applications involving water treatment. Additionally, it is used in the extraction of base metals, like copper and nickel, critical to the evolving energy transition and electrification initiatives,” Ms. Manstan, said.

So, while regenerated acid saves spent acid from becoming waste, it is also responsible in part for reducing emissions by improving fuel efficiency and curbing reliance on fossil fuels.

“Disposal of spent sulfuric acid is the only alternative to regeneration and is cost prohibitive,” Ms. Manstan said. “The regeneration option prevents the disposal of millions of tons of hazardous waste by managing this valuable commodity as a recoverable raw material.”

How Do You Ship Regenerated Sulfuric Acid?

Ecoservices uses a combination of truck, rail and barge to ship regenerated acid to its customers, with rail playing a vital role in the company’s circular loop.

Union Pacific aids in the circularity of sulfuric acid by moving spent acid from refineries in tank cars to Ecoservices. The company regenerates the spent acid, and Union Pacific transports the tank cars of fresh acid to Ecoservices customers.

Why Ship Sulfuric Acid by Rail?

Ecoservices ships spent and regenerated sulfuric acid by rail in tank cars

Rail is the most environmentally responsible way to move freight on land; on average, trains are up to four times more fuel efficient than trucks, so by comparison, moving freight by rail reduces greenhouse gas emissions by up to 75%. Given that regenerated acid is sustainable by nature, it makes sense to ship a recycled product using a shipping mode that has a lower environmental impact.

“Because of the efficiency of the large volume capacity of rail, this mode of shipping eliminates waste in terms of fossil fuel usage, emissions and flexibility,” Ms. Manstan said.

In terms of costs, rail typically offers a lower cost per ton mile than truck, which Ms. Manstan said is another advantage. “Sulfuric acid is the largest commodity chemical in the world and is usually moved in very large quantities to achieve the most cost-effective supply chain,” she said. “Rail fulfills that goal for several continental end-users.”

Learn More

To learn more about Ecovyst, visit their website. To learn more about shipping your products by rail, answer a few questions and an expert will be in touch.

Related Articles

- The Rail Industry Is Saving Millions of Gallons of Fuel a Year – And They’re Using “Cruise Control” to Do It

- Freight Shipping and Its Impact on Climate Change

- A Historic Hemp Shipment

- Rail: An Environmentally Responsible Way to Ship

- Transportation Modes Revealed: A Comprehensive Look

- Quiz: Is Rail the Right Fit for Your Shipments?

- Plastics and the Circular Economy: Is Transportation the Missing Piece?

- Working for a Sustainable Tomorrow: WM’s Approach to Mitigating Climate Change

- Can Transportation Solve the Landfill Problem?

- How Are Locomotives Getting More Fuel Efficient for the Railroad Industry?