If you ship fresh, refrigerated or frozen goods by rail, you’re probably familiar with refrigerated boxcars, also known as “reefers.” These rail cars keep things like pre-packaged foods, meat, seafood, potatoes, onions, carrots, cheese, french fries, frozen vegetables and other produce and dairy products at optimal temperatures during transit.

Although a reefer’s refrigeration unit can be set for the temperature needed to keep products safe during shipping, the steps shippers take when loading and unloading refrigerated boxcars are also important for maintaining temperature and the integrity of the product. To ship fresh, frozen and refrigerated products safely and save fuel in the meantime, follow this list of reefer loading and unloading tips.

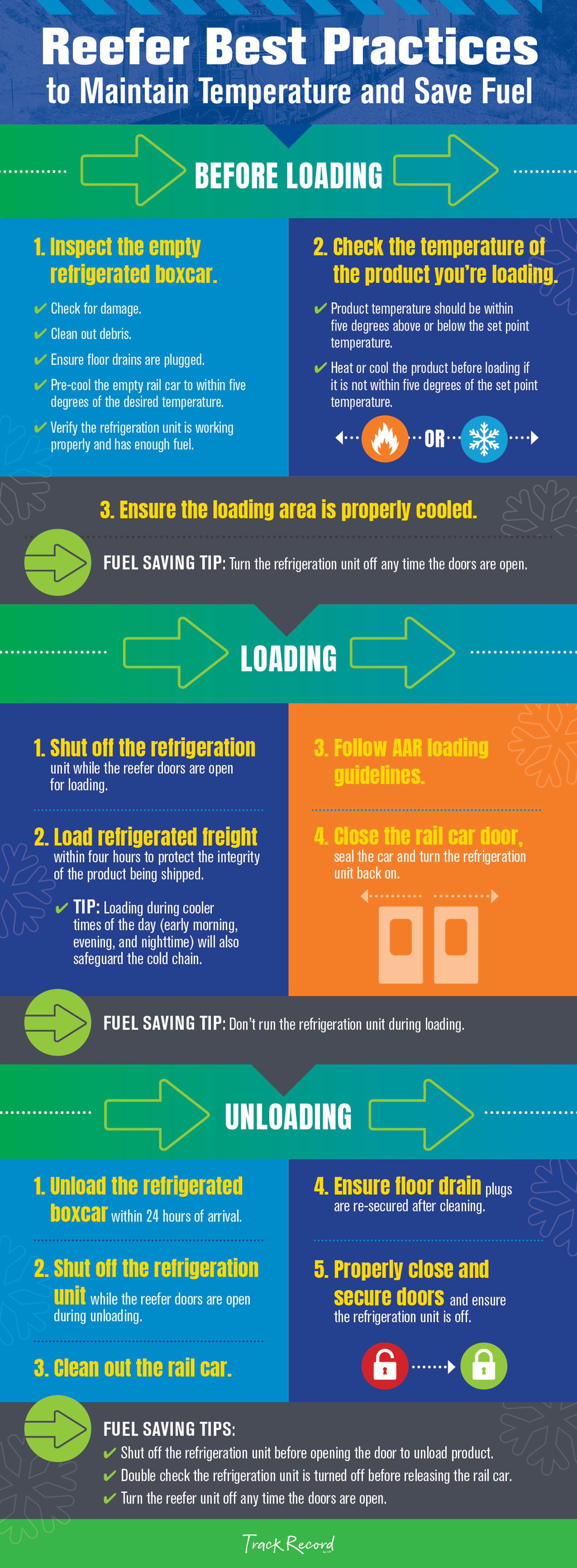

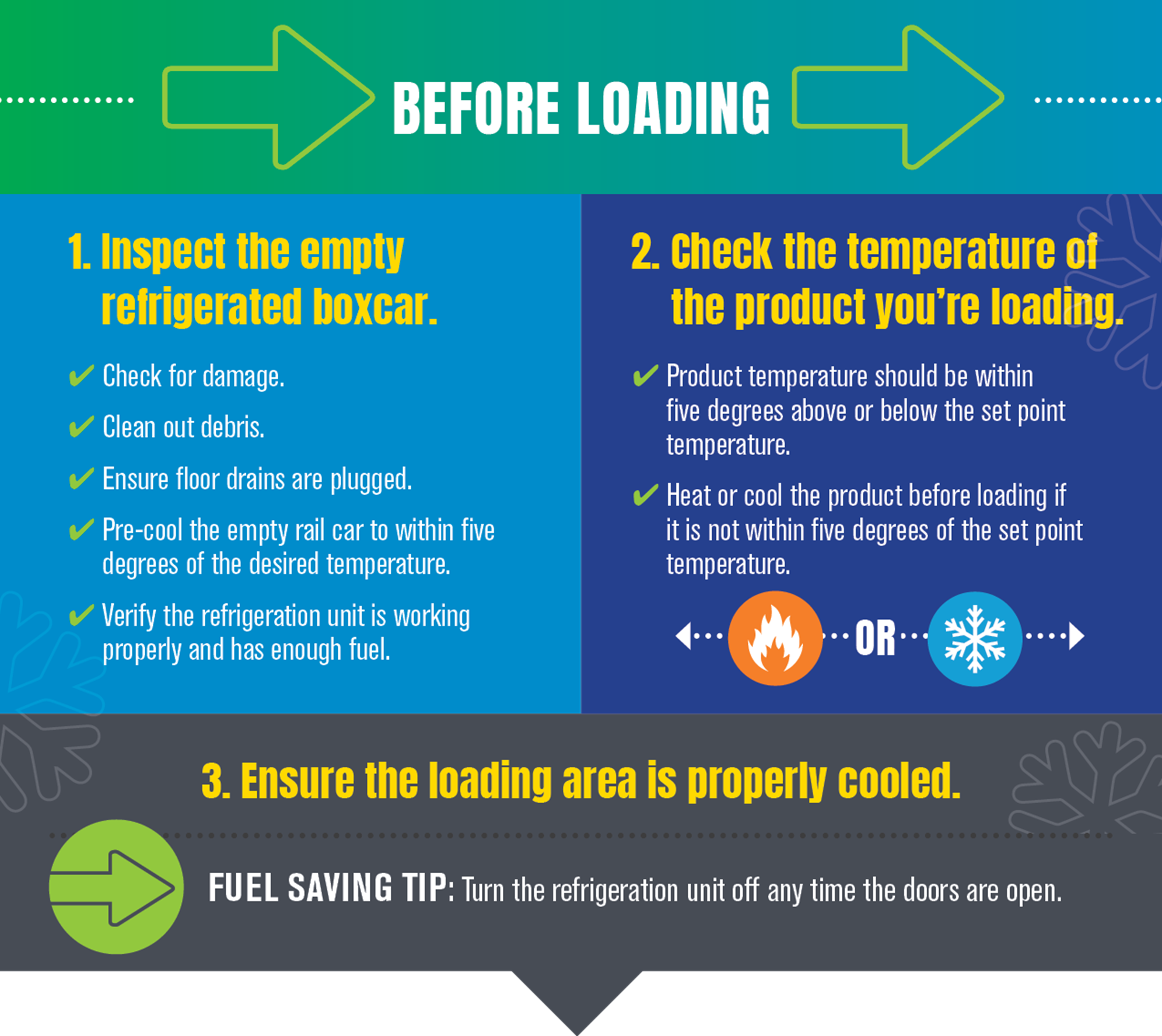

Before Loading

1. Inspect the empty refrigerated boxcar.

- Check for damage that might compromise the temperature, including major damage to ceiling panels, side walls and doors.

- Sweep and clean out any debris.

- Ensure floor drains are plugged. Drain covers should be located at all four corners, both inside the rail car underneath the floor as well as under the outside corners of the car.

- Pre-cool the empty rail car to within five degrees of the desired temperature (also called the “set-point” temperature).

- Verify the refrigeration unit is working properly and make sure it has enough fuel for it to operate for the duration of the trip.

2. Check the temperature of the product you’re loading.

- The product’s core temperature should not be more than five degrees above or below the set point of the rail car.

- If the refrigerated boxcar is cooled to the set point temperature but the product is five degrees above or below that temperature, do not load products until their temperature is within the set point range (e.g., potatoes harvested in the summer may need to be cooled before loading).

- Tip: It’s important to note that, if properly pre-cooled, refrigerated boxcars are designed to maintain temperature. The refrigeration unit is not intended to either increase or decrease the product temperature during freight transportation.

3. Ensure the loading area is properly cooled and the rail car and refrigeration unit are functioning properly to prevent temperature loss during transit.

Fuel Saving Tip: Turn the refrigeration unit off any time the doors are open.

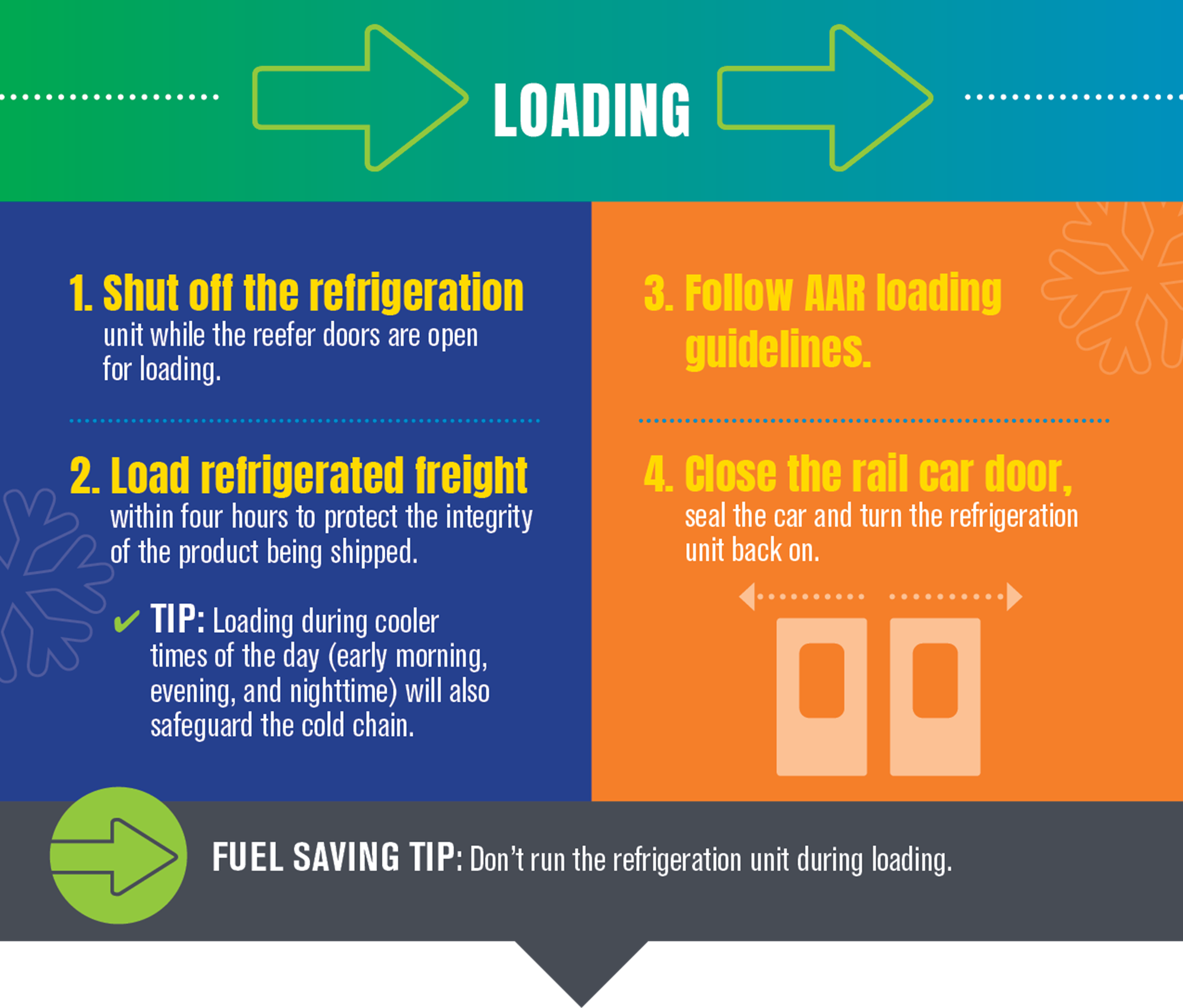

Loading

1. Shut off the refrigeration unit while the reefer doors are open for loading.

- This will protect freight from humidity-related freezing or thawing.

- It will also prevent overworking the refrigeration unit, which can lead to future failures.

2. Load refrigerated freight within four hours or less to protect the integrity of the product being shipped.

- Tip: Loading during cooler times of the day (early morning, evening, and nighttime) will also safeguard the cold chain.

3. Follow AAR loading guidelines and dimensional restrictions to protect rail car airflow and ensure the integrity of the product.

4. Close the rail car door, seal the car and turn the refrigeration unit back on.

- Use bolt seals or cable seals with a minimum diameter of 1/8”. If available, use the refrigerated boxcar’s high security hasp as an additional security measure.

- Ensure the refrigeration unit is running properly and verify refrigeration controls are programmed to the correct settings.

Fuel Saving Tip: Don’t run the refrigeration unit during loading.

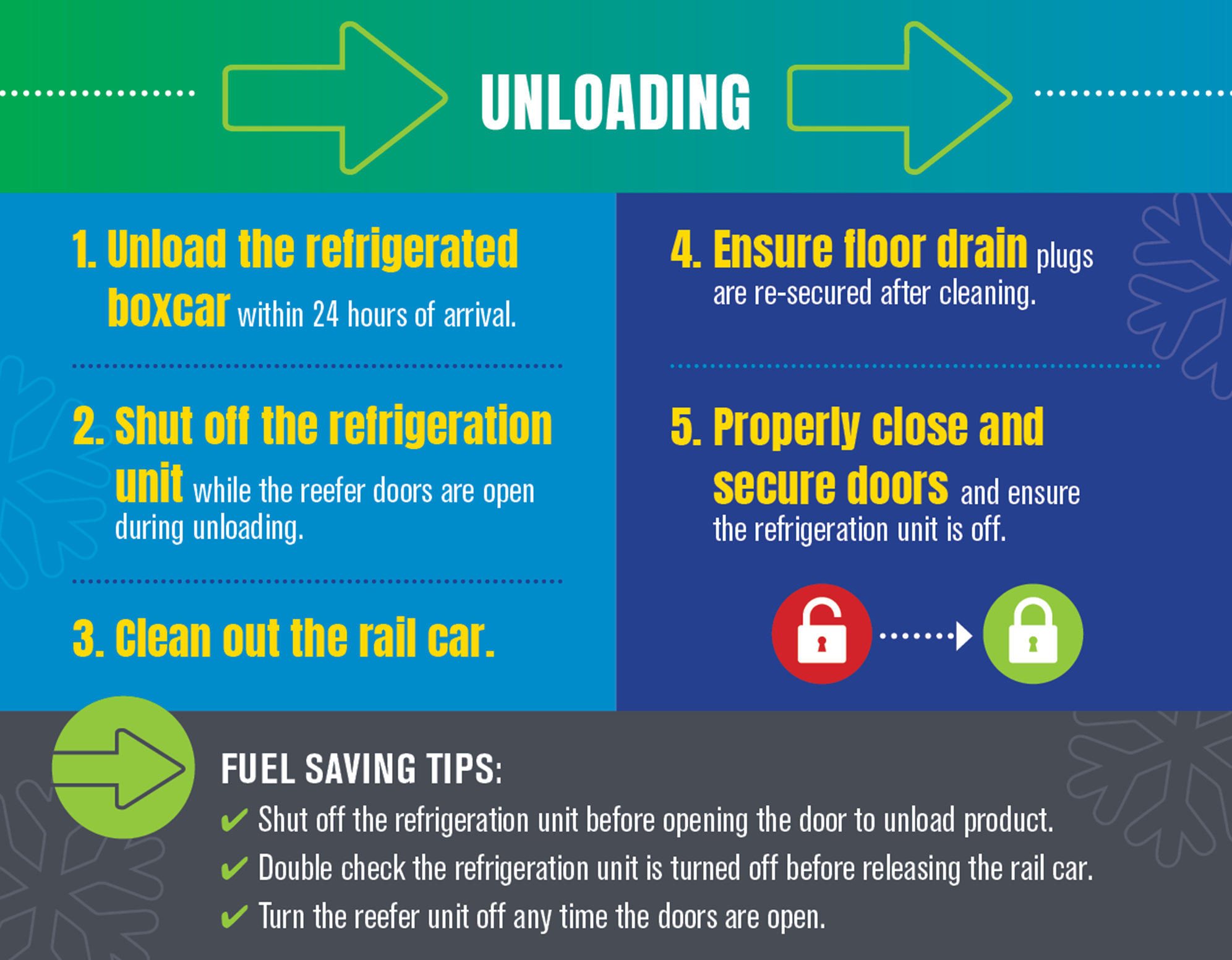

Unloading

1. Unload the refrigerated boxcar within 24 hours of its arrival at the destination.

2. Shut off the refrigeration unit while the reefer doors are open during unloading.

3. Completely unload all product, packaging, and dunnage material and fully clean out the rail car.

4. Ensure floor drain plugs are re-secured after cleaning.

5. Properly close and secure doors and ensure the refrigeration unit is off.

Fuel Saving Tips:

- Shut off the refrigeration unit before opening the door to unload product.

- Double check the refrigeration unit is turned off before releasing the rail car.

- Turn the reefer unit off any time the doors are open.

Bonus Tip: Choose the Best Reefer

Taking the above steps can help keep fresh, frozen and refrigerated products safe during transit. But the way a refrigerated boxcar is designed and built plays a role in maintaining the refrigerated temperature. Shipping products in reefers with the best insulation, airflow, seals and car construction is another choice shippers can make to keep perishable products safe during transit. Learn more and compare refrigerated boxcar options here.

Learn More

To learn more about shipping fresh, frozen and refrigerated products by rail, answer a few questions and an expert will be in touch. To hang on to the above tips, download this printer-friendly infographic.

Related Articles

- Which Reefer Unit Is the Best for Shipping Perishable and Frozen Goods?

- How to Load a Rail Car for Safe Freight Shipping

- How to Prevent Train Derailments on Privately Owned Tracks

- 12 Tips for Shipping Fresh, Refrigerated and Frozen Goods

- Quiz: Is Rail the Right Fit for Your Shipments?

- How Rail Supports America's Food Production...and Helps Feed the World

- Transportation Modes Revealed: A Comprehensive Look

- Cook at Home with These Five Easy Recipe Ideas — Brought to You by Rail

- How to Get Rail Service: Three Ways to Connect with Rail