Dairy products, frozen foods, produce. These are the kinds of products that can spoil when they ship. How do they stay cold between Point A and Point B? Reefers. But not all reefers are created equal. Which is the best choice to keep perishable products safe during transit? These answers to commonly asked questions about reefers will help you compare reefer options and decide for yourself.

What Is a Reefer?

Reefers are refrigerated truck trailers or refrigerated boxcars that ship by truck and train respectively. Equipped with refrigeration units, reefers keep temperature sensitive products safe during transit.

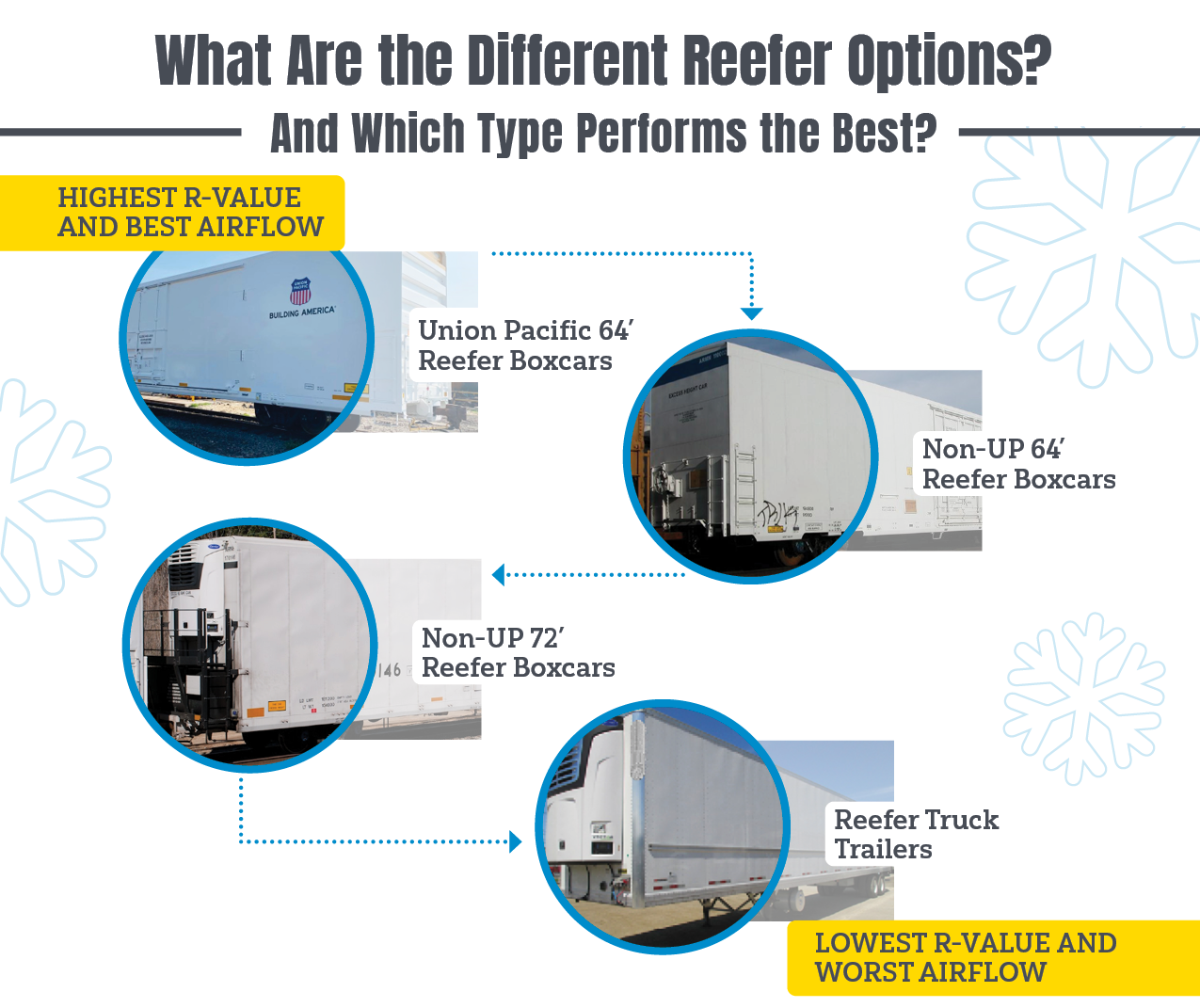

What Are the Different Reefer Options?

Reefers come in the following options, one of which moves by truck and the following three that move by rail:

- Reefer Truck Trailers

- 72’ Reefer Boxcars (interior length)

- Traditional 64’ Reefer Boxcars (interior length)

- Next Generation 64’ Reefer Boxcars (interior length)

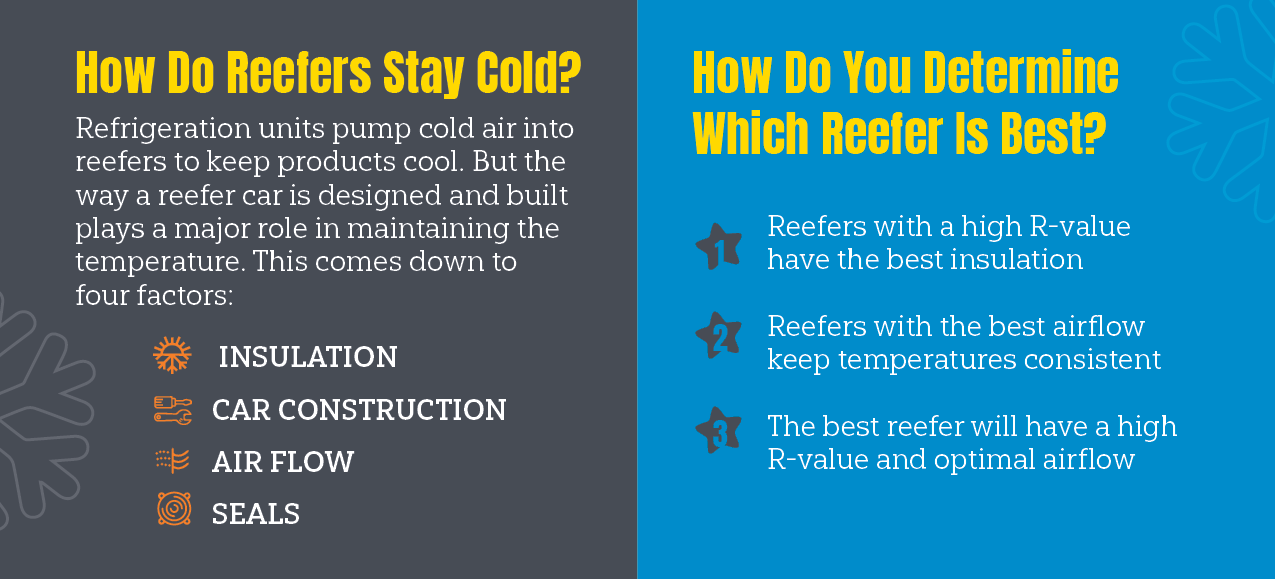

How Do Reefers Stay Cold?

Refrigeration units pump cold air into reefers to keep products cool. But the way a reefer car is designed and built plays a major role in maintaining the temperature. This comes down to four factors:

- Insulation

The type of insulation used in a reefer unit makes a big impact on how well it can maintain the proper temperature. Different types of insulation are given thermal resistance ratings called “R-values,” which indicate how well the material resists conductive heat flow (i.e., heat loss). The higher the R-value, the better it insulates. A superior insulator like polyurethane foam has an R-value of 4, whereas an inferior insulator like concrete has an R-value of 1. In addition to using the optimal insulation, the way the foam is applied is critical in ensuring it has the proper density and covers the entire area. Not following the critical processing and application requirements will reduce the R-value of the foam and create voids within the critical area.

- Car Construction

The supports used in car construction are much like the supports used in building the external walls of a house. Supports are an important part of the equation in reefer cars, since the type used affects how well they maintain their temperature and the R-value. Minimizing the number of supports that are metal, which is a conductor, keeps the car from heating up faster. Those built with reinforced fiberglass supports will maintain temperatures better due to their lower conductivity.

- Air Flow

The only way to keep the temperature consistent throughout a reefer car and keep products evenly cooled is to ensure air is flowing evenly around and through it. Air flow within Union Pacific Railroad reefer cars is measured by several remote interior sensors in different areas of the reefer car measuring temperatures over time. The closer the temperatures are between the sensors to the set point temperature, the better the airflow. The design of the interior of a reefer will determine the quality of air flow around a customer’s commodity.

- Seals

When a car leaks air, it reduces the thermal performance greatly. Whether it’s a reefer truck trailer or reefer box car, the greatest area for air leakage is around the door perimeter. For that reason, Union Pacific Railroad integrated a secondary seal around the perimeter of the door of its reefer cars to keep air from escaping or entering into the car. This helps maintain a consistent temperature around the product during transit.

Which Reefer Type Performs the Best?

Reefers with the highest R-value and optimal airflow will do the best job of keeping products at their optimal temperatures. Union Pacific’s newly designed, next-generation 64’ refrigerated boxcars are designed for maximum insulation and consistent air flow, allowing them to keep perishable products cooler than reefer truck trailers and older refrigerated boxcars.

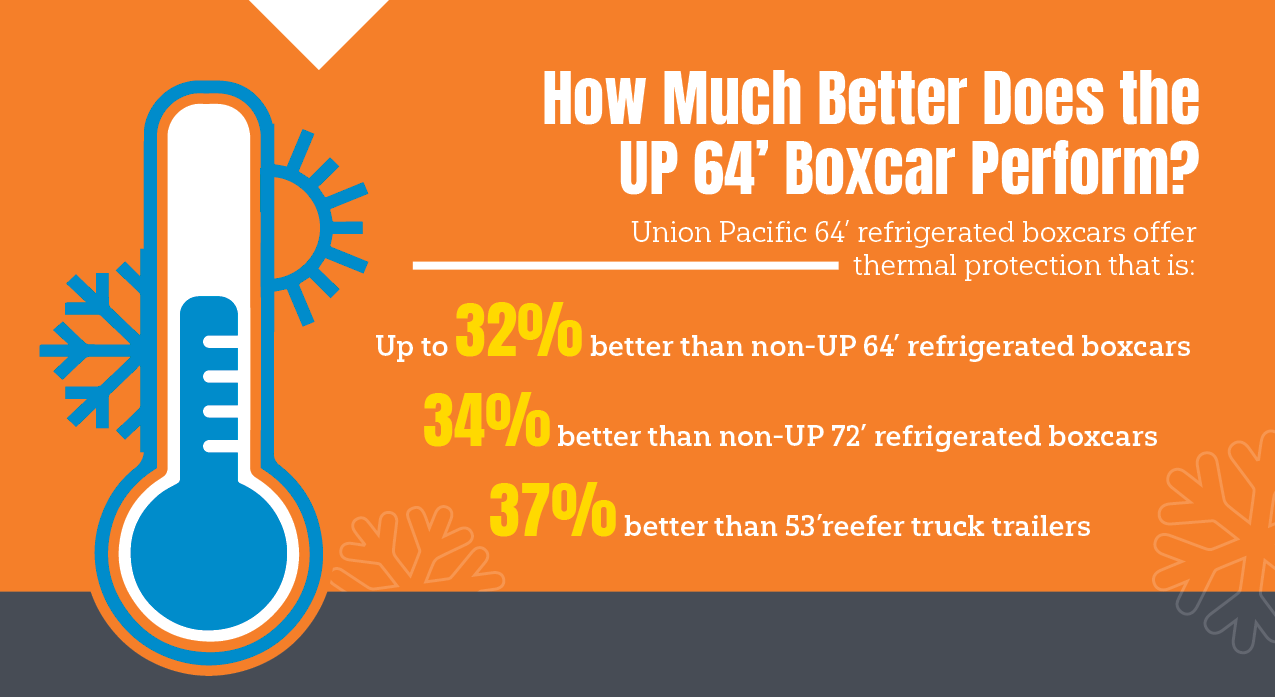

How Much Better Does the Union Pacific 64' Boxcar Perform?

Compared to other reefer types, the thermal performance of the next-generation Union Pacific 64’ reefer is:

- 26% better than traditional 64’ refrigerated boxcars

- 34% better than 72’ refrigerated boxcars

- 37% better than 53’reefer truck trailers

Why Is Thermal Performance Important?

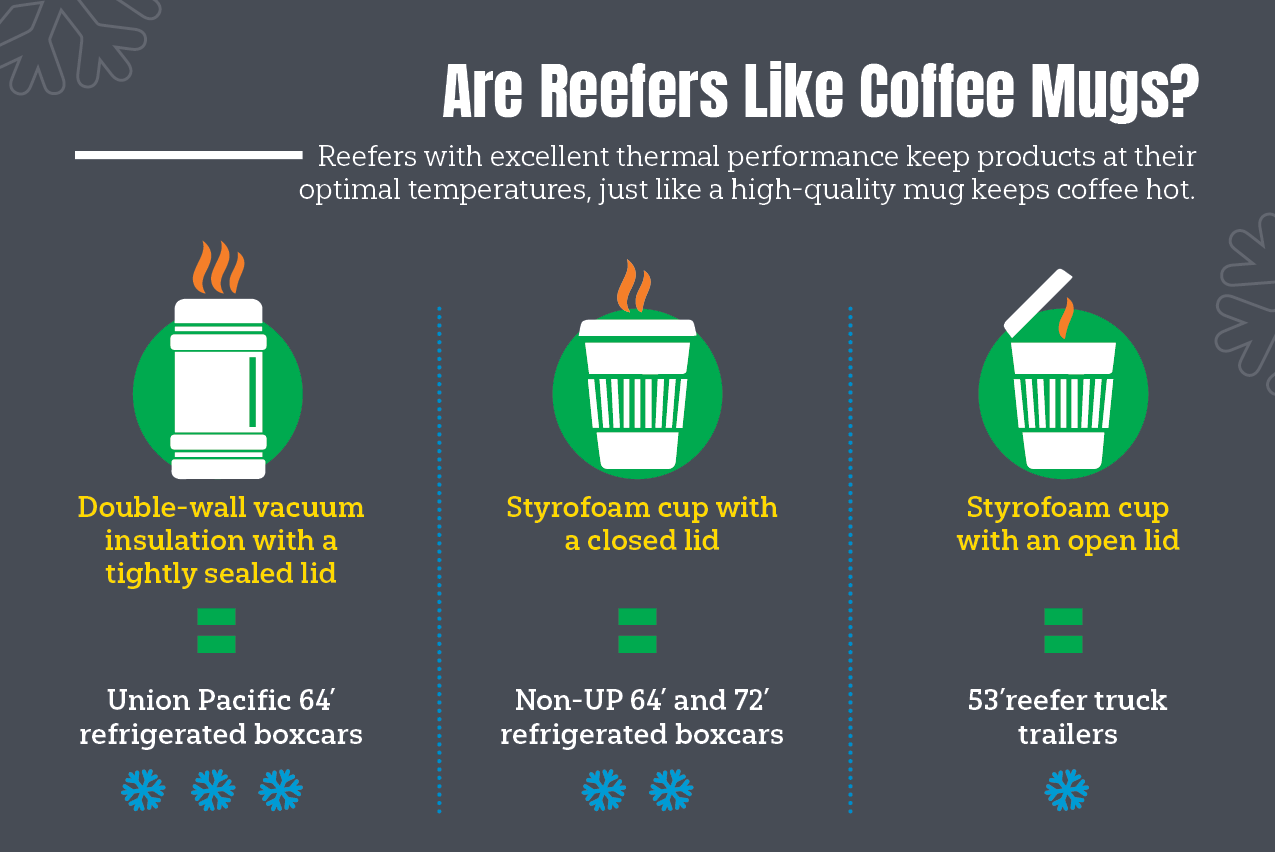

A reefer’s thermal performance is a lot like your coffee mug. The better a coffee mug is designed and insulated, the longer your coffee will stay the same temperature as when you poured it. The same is true for a reefer – the better it is at maintaining a consistent temperature, the safer the product stays during transit.

Typically, the bigger or longer the unit is, the harder it is to cool. But because of the state-of-the-art design of Union Pacific’s new 64’ refrigerated boxcar, it’s able to cool more efficiently than even a 53’ truck trailer.

When a reefer has optimal thermal performance, the unit is more fuel efficient and doesn’t have to work as hard to maintain a consistent temperature. That ultimately results in fewer breakdowns, and fewer chances of spoilage.

So which would you choose to safely ship your product?

Learn More

If you want to learn more about shipping perishable goods like frozen and refrigerated foods and produce, get in touch.

Related Articles

- What Is a Refrigerated Boxcar — and How Do They Keep Shipments Cold?

- 12 Tips for Shipping Fresh, Refrigerated and Frozen Goods

- Quiz: Is Rail the Right Fit for Your Shipments?

- How Rail Supports America's Food Production...and Helps Feed the World

- Transportation Modes Revealed: A Comprehensive Look

- Cook at Home with These Five Easy Recipe Ideas — Brought to You by Rail