November 26, 2024

Union Pacific Technical Training Breaks the Mold with 3D Printing

“Practicing maneuvers with detailed 3D-printed aides significantly boosts student understanding,” said Kimberly Whiting, senior manager-Transportation Technical Training. “We’re helping bridge the gap between theory and real-world application.”

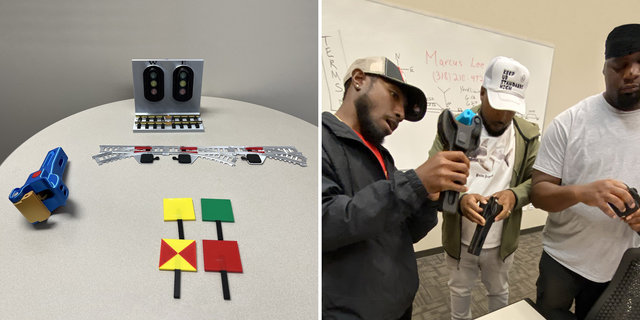

The 3D printings include realistic models of essential rail components, ranging from locomotive brake systems and couplers to rails, ties, switches and signals. All three of the railroad’s largest Operating crafts – Transportation, Engineering and Mechanical – are tapping into the technology’s potential.

“Our Transportation new hires gain a better grasp of how switches work when they can handle a replica with moving parts,” said Robert Baumgardner, senior instructor-Transportations. “We’re also 3D printing knuckles and drawbars, providing safe, hands-on training to demonstrate how the two pieces link rail cars together.”

Mechanical is 3D printing life-sized locomotive wheels, allowing trainees to measure and assess multiple wheels without taking a locomotive out of service – an innovative approach that’s saving 50 minutes per assessment.

In Engineering, trainees practice identifying and troubleshooting real-world challenges on 3D-printed rails and ties; the lightweight replicas are easier and more cost-effective to ship and set up for offsite trainings.

Since incorporating its first 3D printer into the railroad’s training lineup in 2022, Union Pacific has expanded its use of the technology to three active printers in Omaha, Nebraska, and Fort Worth and Houston, Texas.

“Other work groups looking for innovative solutions have started to reach out for help printing items,” said Desrie Valdez, senior manager-Engineering and Mechanical Technical Training. “I’m sure this idea will continue to grow as we identify new ways to incorporate this cutting-edge technology into Union Pacific’s world-class training program.”

Did You Know?

Mastering technical skills in the railroad industry requires a strong understanding of mechanical systems, safety protocols and operational procedures. In 2023, Union Pacific employees received more than 2.6 million hours of best-in-class training.

Breaking the Mold with 3D Printing

Lightweight 3D-printed training aids enable new hires to practice essential skills before they step foot into a rail yard.