Specifications for Pipelines with Maximum Casing Diameter Of 48 Inches and Encased Gas Transmission Lines Crossing Under Railroad Tracks

For Flammable Substances

- Scope

Pipelines included under these specifications are those installed to carry oil, gas, gasoline, or other Flammable or highly volatile substances.

- Installation

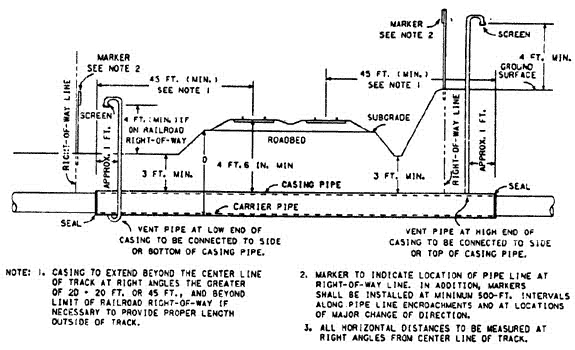

Pipelines under railroad track and right-of-way shall be encased in a larger pipe or conduit installed as indicated in Fig. 1.

The casing pipe or conduit is the essential feature of the plan. Some of the other features as described in following paragraphs are optional in certain cases.

- Carrier Pipe

Carrier pipe inside of casing under railroad Track and right of way shall be of good construction of steel, wrought iron, cast iron, pure or alloyed iron; and shall be either seamless or substantially welded pipe, with welded coupling, or other "approved" joints. Pipe shall be laid with slack (no tension or compression) in the line. Use of a carrier pipe of material other than the above mentioned iron or steel must be approved by the chief engineer of the railroad.

- Casing Pipe

Casing pipe and joints shall be uniformly thick steel construction approved by the railroad's chief engineer and shall be capable in its entirety of withstanding load of railroad roadbed, track and traffic; also shall be constructed so as to prevent leakage of any matter from the casing or conduit throughout its length under track and railroad right of way.

The casing shall be installed with even bearing throughout its length, and to prevent formation of standing liquids shall slope to one end.

Wall thickness of the casing must be no less than that specified in the attached steel casing pipe wall thickness chart.

Inside diameter of the casing shall be at least 10% larger than the outside diameter of the carrier pipe but no less than 2 inches greater than largest outside diameter of carrier pipe, joints or couplings.

- Cathodic Protection

Where cathodic protection is used on the carrier pipe, an above ground test box constructed specifically for this purpose will be provided adjacent to casing vent pipe with test wires attached to casing wall and carrier pipe, as shown in Fig. 1.

- Seals and Vents

Where ends of casing are below ground, they shall be suitably sealed to outside of carrier pipe against intrusion of foreign material which might prevent ready removal of the carrier pipe. Also, the casing must be properly vented above ground with vent pipes having inside diameter equal to 10% of nominal size of the carrier pipe but no less than 2 inches and extending not less than 4 feet above ground surface. Vent pipe at low end of casing shall be connected with bottom of casing and vent at high end shall be connected with top of casing. Top of vent shall be fitted with down-turned elbow properly screened.

- Depth of Casing

The depth from base of railroad rail to top of casing at its closest point shall not be less than 4.5 feet and on other portions of railroad right-of-way where casing is not directly beneath any track the depth from surface of right of way, and from bottom of ditches to top of casing, shall not be less than 3 feet. Where it is not possible to secure the above depths, special construction shall be used as approved by the railroad's chief engineer.

- Length of Casing

Casing shall extend at least 45 feet or 2(D)+20 feet, (where "D" equals depth of the bottom of the casing below railroad subgrade), whichever is greater, each side from (measured at right angles to) centerline of outside track. The casing is to extend beyond the limit of the railroad right-of-way as required to obtain the specified length. If additional tracks are constructed in the future, the casing shall be correspondingly extended at the utility's expense. When a carrier pipe other than iron or steel is allowed, then the pipe must be encased in steel for its entire length on railroad right of way or that length determined above, whichever is greater.

- Jacking Pits

Jacking pits shall be a minimum of 30 feet from the centerline of track.

- Shut-Off Valves

Where warranted by special local conditions as determined by the railroad company, accessible emergency shutoff valves shall be installed within effective distances at each side of the crossing.

- Location

Pipelines shall where practicable, be located to cross tracks at approximately right angles thereto and said crossing shall not be closer than 150 feet to any portion of any railroad bridge, building, or other important structure, nor to any switch unless specifically approved by the chief engineer.

Pipelines, casing pipe and vent pipes shall be at least 16 feet (vertically) from aerial electric wired and shall be suitably insulated from underground conduits carrying electric wires on railroad right of way.

- Topography

Pipelines carrying extremely high pressure, volatile or highly flammable material shall, where practicable, be located where the ground surface slopes downward away from the railroad tracks. Also, when large capacity pipes are located where the ground surface ascends above the railroad roadbed, there must be sufficient adjacent opening under the tracks to carry off the material in event of rupture.

- Restoration of Right of Way

Upon completion of the pipeline installation work, all rubbish, excess materials, temporary structures and equipment are to be removed and the railroad's right of way cleaned and restored to the satisfaction of the railroad's chief engineer or his authorized representative. Disturbed areas shall be seeded or otherwise protected to control erosion as specified by the chief engineer of the railroad.

- Approval of Plans

Plans for a proposed pipeline shall be submitted to and meet the approval of the chief engineer of the railroad or his authorized representative before work is begun and all work on railroad right of way, including the supporting of the track or roadbed, shall be subject to his inspection and direction. All costs incurred shall be borne by the utility.

For Non-flammable Substances

- Scope

Pipelines included under these specifications are those installed to carry steam, water or any nonflammable substance which from its nature or pressure might cause damage if escaping on or in the vicinity of railroad property.

- Installation

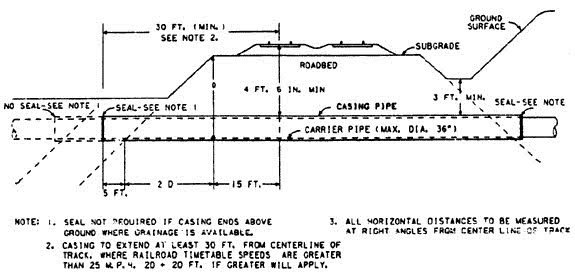

Pipelines under railroad track and right of way shall be encased in a larger pipe or conduit installed as indicated in Fig. 2.

The casing pipe or conduit is the essential feature of the plan. Some of the other features as described in following paragraphs are optional in certain cases.

- Carrier Pipe

Carrier pipe inside the casing under the railroad track and right of way shall be of good construction approved by the chief engineer of the railroad.

- Casing Pipe

Casing pipe and joints may be of any conduit construction approved by the railroad's chief engineer and shall be capable of withstanding the load of railroad roadbed, track and traffic; also shall be constructed so as to prevent leakage of any matter from the casing or conduit throughout its length under track and railroad right of way. The casing shall be installed so as to prevent the formation of a waterway under the railroad.

Casing shall be installed with even bearing throughout its length and shall slope to one end.

Wall thickness of the casing must be no less than that specified in the attached steel casing pipe wall thickness chart.

The inside diameter of the casing shall be no less than 2 inches greater than largest outside diameter of carrier pipe, joints or couplings.

- Cathodic Protection

Where cathodic protection is used on the carrier pipe, a flush test box constructed specifically for this purpose will be provided with test wires attached to casing wall and carrier pipe, as shown in Fig. 2.

- Seals

The ends of the casing shall be suitably sealed to outside of carrier pipe against the intrusion of foreign material which might prevent ready removal of the carrier pipe.

- Depth of Casing

The top of the casing pipe shall be below the frost line, and its closest point shall not be less than 4.5 feet below base of railroad rail. On other portions of the railroad right of way where casing is not directly beneath any track the depth from the surface of the ground and from bottom of ditches to top of casing, shall not be less than 3 feet. Where it is not possible to secure the above depths, special construction shall be used as approved by the railroad's chief engineer.

- Length of Casing

Casing shall extend at least 30 feet or 2(D)+20 feet, (where "D" equals depth of the bottom of the casing below railroad subgrade), whichever is greater, each side from (measured at right angles to) centerline of outside track. The casing is to extend beyond the limit of the railroad right of way as required to obtain the specified length. If additional tracks are constructed in the future, the casing shall be correspondingly extended at the utility's expense.

- Jacking Pits

Jacking pits shall be a minimum of 30 feet from the centerline of track.

- Shut-Off Valves

Where warranted by special local conditions and when mutually agreed to by the railroad company and the owner of the pipeline, accessible emergency shutoff valves shall be installed within effective distances at each side of the crossing.

- Location

Pipelines shall, where practicable, be located to cross tracks at approximately right angles thereto and said crossing shall not be closer than 150 feet to any portion of any railroad bridge, building, or other important structure.

Pipelines and casing pipe shall be at least 16 feet (vertically) from aerial electric wired and shall be suitably insulated from underground conduits carrying electric wires on railroad right of way.

- Topography

Where practicable, pipelines shall be located where the ground surface slopes downward away from the railroad tracks. Also, when large capacity pipes "are located where the ground surface ascends above the railroad roadbed, there must be sufficient adjacent opening under the tracks to carry off the material in event of rupture.

- Restoration of Right of Way

Upon completion of the pipeline installation work all rubbish, excess materials, temporary structures and equipment are to be removed and the railroad's right of way cleaned and restored to the satisfaction of the railroad's chief engineer or his authorized representative. Disturbed areas shall be seeded or otherwise protected to control erosion as specified by the chief engineer of the railroad.

- Approval of Plans

Plans for a proposed pipeline shall be submitted to and meet the approval of the chief engineer of the railroad or his authorized representative before work is begun and all work on railroad right of way, including the supporting of the track or roadbed, shall be subject to his inspection and direction. All costs incurred shall be borne by the utility.

Steel Casing Pipe Wall Thickness Chart

| Minimum Thickness | Diameter Of Casing Pipe |

| 1/4" (0.2500") | 12" or less |

| 5/16" (0.3125") | over 12"-18" |

| 3/8" (0.3750") | over 18"-22" |

| 7/16" (0.4375) | over 22"-28" |

| 1/2" (0.5000") | over 28"-34" |

| 9/16" (0.5625) | over 34"-42" |

| 5/8" (0.6250") | over 42"-48" |

This chart is only for smooth steel casing pipes with minimum yield strength of 35,000 psi.

Casing pipes larger than 48" diameter or with any portion deeper than 20' shall be submitted to chief engineer of the railroad for approval.

Diagrams of Common and Engineering Standards

- Fixed Object Identity

- Mile Marker

- Culvert Marker

- Bridge Number Sign

- General Shoring Requirements (1MB)